Application scenario of Fiberglass Geogrid

Application Scenario of Fiberglass Geogrid – Strengthening Infrastructure for the Long Term

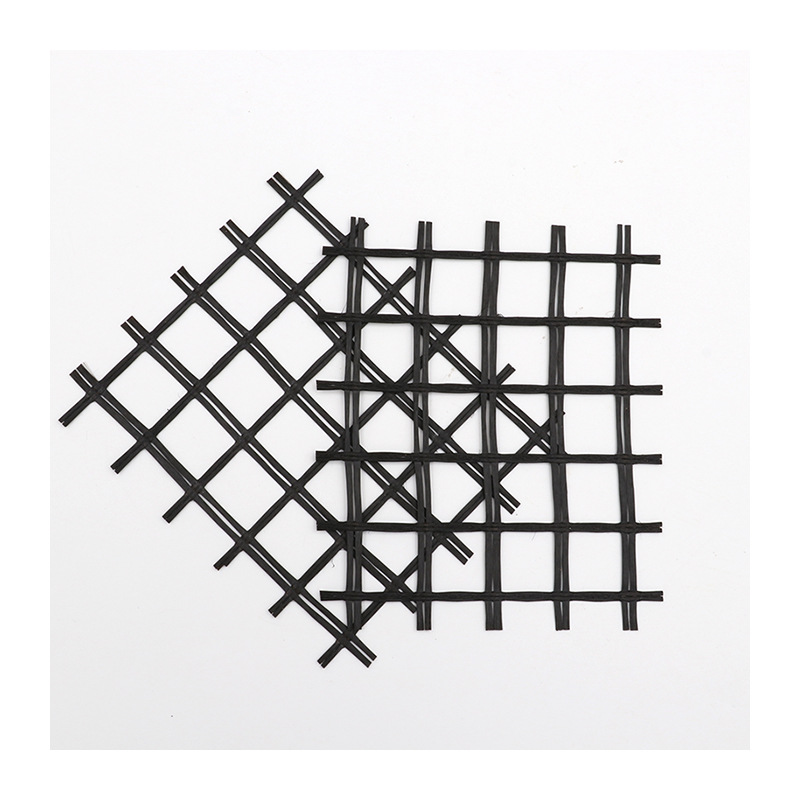

Fiberglass geogrid is a high-performance geosynthetic material widely used in civil engineering, road construction, and soil stabilization. Known for its high tensile strength, excellent chemical resistance, and dimensional stability, fiberglass geogrid plays a crucial role in reinforcing pavements, extending infrastructure life, and reducing maintenance costs.

In this article, we explore the application scenario of fiberglass geogrid, highlighting its key uses, benefits, and real-world deployment in various construction environments.

? What is Fiberglass Geogrid?

Fiberglass geogrid is a grid-like material made from woven fiberglass yarns coated with a protective polymer (such as PVC). Its rigid and stable structure enables it to distribute loads evenly, prevent reflective cracking in asphalt layers, and reinforce weak subgrades.

The application scenario of fiberglass geogrid spans across multiple sectors, from highways to railways, airports, parking lots, and industrial yards. Its unique properties make it ideal for both new construction and pavement rehabilitation projects.

?️ Main Application Scenarios of Fiberglass Geogrid

Here are the key application scenarios of fiberglass geogrid in civil engineering and construction:

1. Asphalt Pavement Reinforcement

One of the most common application scenarios of fiberglass geogrid is in road construction. It is installed between asphalt layers to:

Prevent reflective cracks

Distribute loads more evenly

Extend pavement lifespan

Improve ride quality and surface integrity

Use Case: Highways, municipal roads, rural roads, and airport runways.

2. Old Road Rehabilitation

In resurfacing or overlay projects, fiberglass geogrid is used to reinforce aging pavement structures without the need for full-depth reconstruction. It:

Reduces cost by minimizing excavation

Controls crack propagation from old layers

Ensures long-term stability of rehabilitated roads

Use Case: Overlay for cracked concrete or asphalt roads.

3. Railway Track Bed Stabilization

For railway infrastructure, fiberglass geogrid helps stabilize the ballast and distribute dynamic loads from moving trains.

Use Case: High-speed railways, cargo railways, and metro systems.

4. Airport Runway Reinforcement

The application scenario of fiberglass geogrid in airports includes reinforcing runways and taxiways to prevent rutting, cracking, and early deterioration caused by heavy aircraft loads.

Use Case: Civil and military airports, heliports.

5. Parking Lot and Port Yard Construction

In commercial and industrial settings, fiberglass geogrid is applied to large open spaces to prevent surface settlement and structural failure under heavy-duty vehicles.

Use Case: Logistics hubs, container yards, and bus depots.

6. Slope and Embankment Reinforcement

While not its primary use, fiberglass geogrid can be applied in retaining wall systems and slopes to control soil erosion and improve stability when used in combination with other geosynthetics.

Use Case: Roads near hilly terrain, cut-and-fill slopes.

✅ Benefits of Using Fiberglass Geogrid in These Scenarios

High Tensile Strength: Resists cracking and deformation under load.

Excellent Temperature Resistance: Performs well in extreme hot or cold climates.

Chemical Stability: Non-reactive to alkaline asphalt and soil environments.

Lightweight and Easy to Install: Reduces labor and equipment costs.

Improved Service Life: Enhances the longevity of roads and structures.

Eco-friendly Construction: Reduces material waste and energy use.

? Technical Properties (Example)

| Property | Specification |

|---|---|

| Material | Alkali-resistant fiberglass yarn |

| Coating | PVC or Bitumen |

| Tensile Strength (MD/CD) | 50–200 kN/m |

| Elongation at Break | < 4% |

| Mesh Size | 25mm x 25mm or customizable |

| Roll Width | 1m – 6m |

| Application Temperature Range | -30°C to +80°C |

? Real-World Project Scenarios

National Highway Projects (India): Used in overlay systems to combat reflective cracking.

Airport Expansion in Africa: Provided reinforcement under new taxiways to accommodate larger aircraft.

Port Logistics in Southeast Asia: Installed under container yards to prevent rutting and surface deformation.

Urban Expressway Renovations (Europe): Successfully used in long-term resurfacing contracts.

? Why Understand the Application Scenario of Fiberglass Geogrid?

Understanding the application scenario of fiberglass geogrid allows engineers, contractors, and project managers to:

Choose the right type of geogrid for each situation.

Design infrastructure that lasts longer and performs better.

Reduce project costs through fewer repairs and lower material usage.