The Gap Between Hdpe and Pvc Geomembrane

The Gap Between HDPE and PVC Geomembrane: Understanding Key Differences in Performance and Application

In the realm of geosynthetic engineering, the gap between HDPE and PVC geomembrane is a critical factor influencing material selection for waterproofing and containment projects. While both geomembranes are widely used for lining ponds, landfills, canals, and industrial reservoirs, their performance characteristics, installation methods, and long-term durability vary significantly. Understanding the gap between HDPE and PVC geomembrane helps engineers, contractors, and decision-makers choose the most suitable material for specific environmental and mechanical conditions.

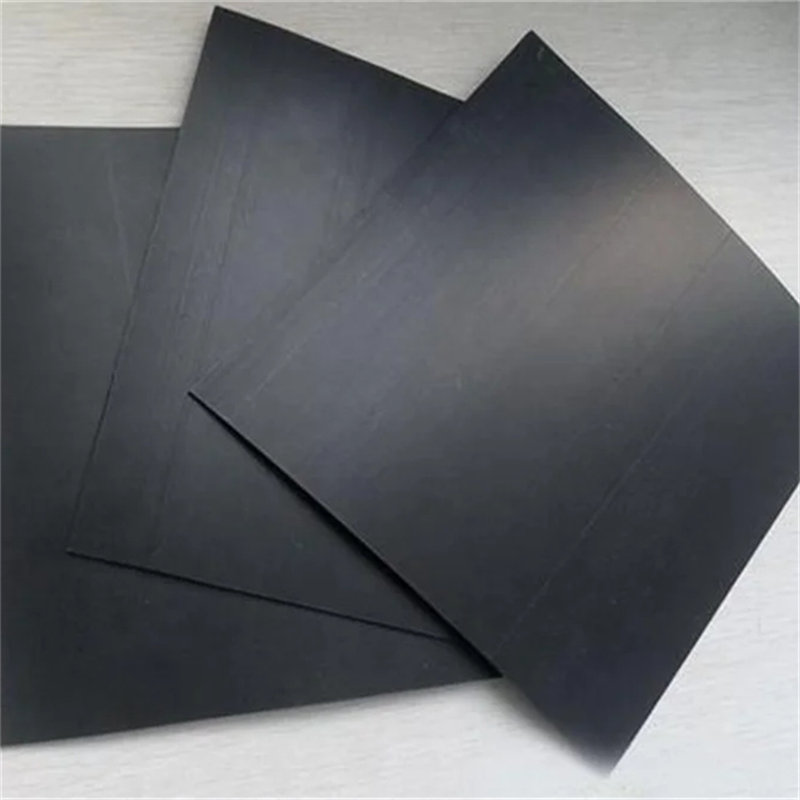

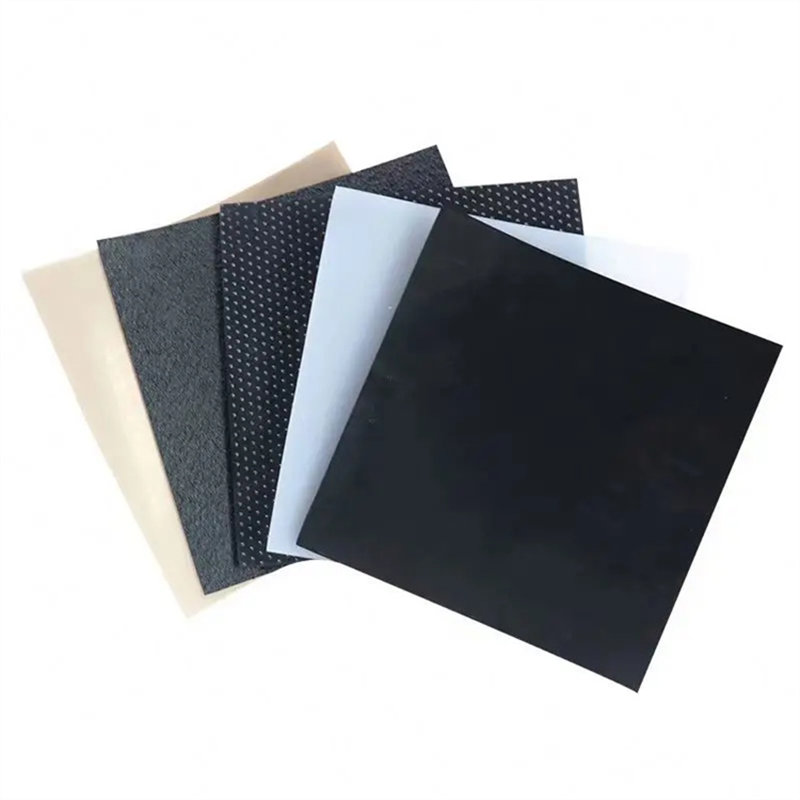

One of the most notable aspects of the gap between HDPE and PVC geomembrane lies in material composition and flexibility. High-Density Polyethylene (HDPE) is a stiffer, more rigid geomembrane known for its exceptional chemical resistance and UV durability. In contrast, Polyvinyl Chloride (PVC) geomembrane is softer and more flexible, which makes it easier to install in complex or confined geometries. This flexibility in PVC allows for faster installation on irregular surfaces, whereas HDPE often requires more precise subgrade preparation and skilled welding.

Durability is another dimension in the gap between HDPE and PVC geomembrane. HDPE geomembranes exhibit outstanding resistance to punctures, stress cracking, and long-term weathering. They are especially well-suited for exposed applications such as mining tailing ponds or hazardous waste landfills. PVC geomembranes, although resistant to many chemicals, tend to degrade more rapidly under UV exposure and may shrink or become brittle over time, particularly in extreme temperature fluctuations. Therefore, for long-term, exposed applications, HDPE often outperforms PVC in overall lifespan and performance consistency.

The chemical compatibility of these materials also contributes to the gap between HDPE and PVC geomembrane. HDPE’s high resistance to aggressive solvents, acids, and hydrocarbons makes it ideal for industrial waste containment and petrochemical environments. PVC geomembrane, while suitable for moderate containment projects, may not perform well under prolonged exposure to harsh chemicals or high pH levels. As such, HDPE is typically preferred in environments with rigorous chemical demands.

When evaluating the gap between HDPE and PVC geomembrane, installation methods and cost implications cannot be ignored. HDPE geomembranes are commonly welded using hot wedge or extrusion welding techniques, creating strong, leak-proof seams. However, this process requires specialized equipment and skilled technicians, which may increase labor costs. On the other hand, PVC geomembranes are often seamed using chemical bonding or heat fusion, allowing for more flexible and cost-effective installation on smaller projects.

Environmental considerations also define the gap between HDPE and PVC geomembrane. HDPE is considered more environmentally stable due to its inert chemical nature and recyclability. It doesn’t contain plasticizers or stabilizers that could leach into the environment over time. PVC, in contrast, often contains additives such as phthalates and chlorine-based compounds, raising potential concerns about environmental impact and long-term leaching, especially in drinking water applications.

In conclusion, the gap between HDPE and PVC geomembrane is evident in their physical properties, chemical resistance, installation techniques, and environmental performance. While both materials have valid roles in modern engineering, the specific needs of a project—such as longevity, flexibility, exposure, and chemical containment—should dictate the optimal choice. By fully understanding the gap between HDPE and PVC geomembrane, project planners can ensure safe, efficient, and long-lasting geomembrane installations tailored to their unique requirements.