How is HDPE geomembrane produced?

How HDPE Geomembrane is Produced

The production of HDPE geomembrane involves a series of processes that transform high-density polyethylene (HDPE) resin into durable, flexible, and impermeable sheets used in various environmental protection and containment applications. These geomembranes are widely used for landfills, ponds, mining operations, and other applications where containment or waterproofing is required. The production process is highly technical and requires precise control of temperature, pressure, and resin properties to achieve the desired quality and performance standards.

1. Selection of Raw Materials

The first step in the production of HDPE geomembrane is the selection of high-density polyethylene (HDPE) resin. HDPE is chosen for its excellent chemical resistance, durability, and high tensile strength. The raw material is typically in the form of small plastic pellets, which are designed to meet specific industry standards for thickness, flexibility, and impermeability.

The quality of the HDPE geomembrane is determined by the purity and grade of the resin. It is crucial that the resin is free from impurities, such as dust or moisture, as these could affect the physical properties of the finished product.

2. Extrusion Process

The most common method for producing HDPE geomembrane is the extrusion process. In this process, the HDPE resin pellets are first fed into a hopper, where they are melted and mixed at high temperatures (around 200-260°C). The resin is then passed through an extruder, which is a large, rotating screw that melts and pushes the material through a die. The die shapes the melted resin into a continuous sheet.

The HDPE geomembrane is extruded at the desired thickness, typically ranging from 0.5 mm to 3 mm, depending on the application. The extrusion process is carefully monitored to maintain consistent thickness and surface quality, as variations can lead to weaknesses in the finished product.

3. Calendering Process

In addition to extrusion, some HDPE geomembrane sheets may undergo a calendering process, where the material is passed between heated rollers to create a smooth, uniform thickness. Calendering is often used to produce geomembranes with smoother surfaces and better dimensional stability. The HDPE geomembrane is then cooled down as it passes through the rollers to harden the material.

4. Cooling and Solidification

Once the HDPE geomembrane is extruded and shaped, it is cooled quickly to solidify the material. This is typically done using water-cooled rollers or air cooling systems. The cooling process ensures that the geomembrane retains its rigidity and dimensional accuracy. It is essential for the material to cool evenly to avoid warping or other forms of deformation.

5. Laminating and Multilayer Construction

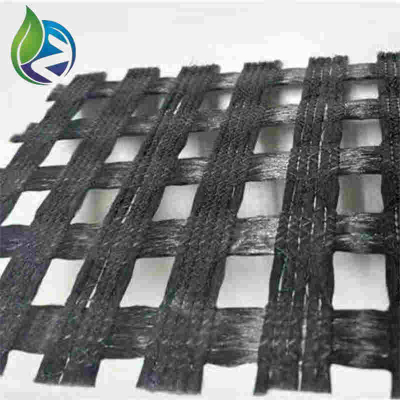

In some cases, HDPE geomembranes may be produced as multilayer structures to enhance performance. This is done by fusing multiple layers of HDPE material together, which can improve strength, durability, and resistance to punctures. For example, some geomembranes are designed with a reinforced layer between two layers of HDPE to provide additional mechanical properties. This process is accomplished by lamination, where the individual layers are bonded together under heat and pressure.

6. Texturing or Surface Treatment

To improve the grip or friction of the HDPE geomembrane, the surface of the material may undergo texturing. Texturing is typically done using a roller with a specific pattern to create a rough surface on one or both sides of the geomembrane. This is particularly important for applications where the geomembrane will be used on slopes or areas prone to shifting, as the textured surface prevents slippage and enhances stability.

7. Quality Control and Testing

Once the HDPE geomembrane has been produced, it undergoes a series of rigorous quality control tests. These tests ensure that the material meets the required standards for strength, impermeability, and durability. Common tests include:

Tensile strength testing to measure the material’s resistance to stretching or breaking under tension.

Elongation at break to assess how much the geomembrane can stretch before failing.

Puncture resistance to test the ability of the material to resist penetration by sharp objects.

Chemical resistance tests to ensure the geomembrane can withstand exposure to various chemicals.

UV resistance testing to evaluate the geomembrane’s ability to resist degradation from exposure to ultraviolet light.

The HDPE geomembrane is also inspected for defects such as holes, air bubbles, or uneven thickness, which could affect its performance.

8. Cutting and Packaging

After passing the quality control tests, the HDPE geomembrane is cut into rolls or sheets according to the specified size for the intended application. The rolls are then carefully packaged to protect them from environmental elements, such as moisture or dirt, during storage and transportation. The packaged geomembranes are ready to be shipped to clients for installation.

Applications of HDPE Geomembrane

The HDPE geomembrane is used in a wide range of applications where environmental protection and waterproofing are required. Some of the most common uses include:

Landfill Liners: HDPE geomembranes are used to prevent the leakage of hazardous materials from landfills into the surrounding environment.

Pond Liners: These geomembranes are commonly used in agriculture and aquaculture for creating waterproof barriers in ponds and tanks.

Mining: In mining operations, HDPE geomembranes are used for heap leaching and tailings ponds to prevent groundwater contamination.

Water Containment: Geomembranes are used in reservoirs, canals, and other water containment structures to prevent seepage and ensure efficient water management.

Conclusion

The production of HDPE geomembrane involves a highly controlled process that combines advanced extrusion, cooling, and surface treatment technologies to create a material that is strong, flexible, and impermeable. As industries demand more durable and efficient solutions for environmental protection and containment, the development of HDPE geomembrane production methods continues to evolve, offering even better performance, sustainability, and cost-effectiveness. This process, from material selection to final testing, ensures that HDPE geomembranes meet the stringent requirements of modern infrastructure projects and environmental protection standards.