Development status of high performance geotextile

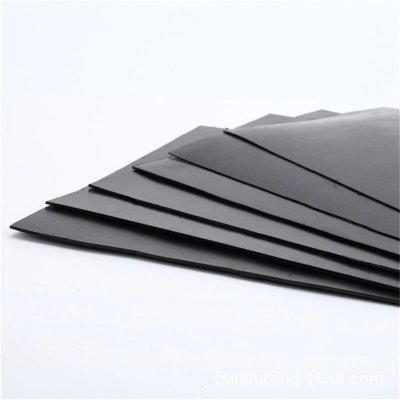

High-performance geotextiles have become a cornerstone in modern civil engineering, environmental protection, and infrastructure projects. Designed for enhanced tensile strength, durability, and permeability, these materials are crucial for soil stabilization, filtration, drainage, and erosion control. The development of geotextiles reflects the evolution of polymer science, manufacturing technologies, and engineering standards worldwide.

Material Composition and Engineering Principles

Materials: Polypropylene (PP), Polyester (PET), and advanced polymer composites.

Fabric Types: Woven, non-woven, and composite geotextiles.

Key Properties:

High Tensile Strength: Supports heavy loads and reinforces subgrades.

Permeability & Filtration: Allows water flow while retaining soil particles.

UV and Chemical Resistance: Ensures long-term outdoor performance.

Dimensional Stability: Maintains integrity under stress and compression.

Current Development Trends

Advanced Fiber Technology: High-tenacity PET and PP fibers for superior strength.

Composite Structures: Combining woven and non-woven layers for multifunctionality.

Functionalization: Hydrophobic coatings, flame retardant treatments, and anti-fouling surfaces.

Eco-Friendly Materials: Biodegradable and recyclable polymers meeting sustainability goals.

Digital Manufacturing: Precision extrusion and needle-punching for uniformity and quality control.

Regulatory Standards and Compliance

ASTM D4595: Geotextile tensile testing.

ASTM D4632: Grab strength method.

ASTM D4751: Apparent opening size (AOS) for filtration.

ISO 10319: International tensile strength standard.

AASHTO M288: Guidelines for roadway applications.

Compliance ensures reliability, safety, and long-term structural performance.

Applications and Examples

Roadway Reinforcement: Stabilizing subgrades and embankments.

Slope and Erosion Control: Riverbanks, dams, and coastal areas.

Drainage Systems: Subsurface drains, French drains, and stormwater management.

Environmental Protection: Landfill liners, sediment control, and reclamation projects.

Operational Considerations

Installation: Surface must be free of sharp debris; proper anchoring is critical.

Overlap: Minimum 12-inch overlap to maintain continuity.

Handling: Avoid excessive folding, stretching, or puncturing during transport.

Inspection: Routine checks ensure longevity and functional performance.

Frequently Asked Questions (FAQ)

Q1: What distinguishes high-performance geotextiles from standard types?

High-performance geotextiles have higher tensile strength, UV resistance, chemical resistance, and multifunctional capabilities.

Q2: Can they be used in extreme climates?

Yes, specially engineered fibers and coatings allow usage in arid, humid, and subzero conditions.

Q3: How long is their service life?

Typically 20–30 years depending on environmental exposure and stress conditions.

Q4: Are these materials environmentally friendly?

Many modern geotextiles use recyclable or biodegradable polymers in line with sustainability goals.

Conclusion & Call to Action

High-performance geotextiles represent the intersection of material science, civil engineering, and environmental technology. With compliance to ASTM, ISO, and AASHTO standards, they offer exceptional strength, filtration, and durability across diverse applications.

Contact us to source high-quality high-performance geotextiles for your next project and ensure superior engineering efficiency and long-term stability.

High-performance geotextiles provide unmatched tensile strength, durability, and filtration performance for infrastructure, environmental, and civil engineering projects. Advanced PP and PET fibers, combined with composite and functionalized structures, ensure superior load-bearing capacity, UV resistance, and chemical stability. Compliance with ASTM D4595, ASTM D4632, ISO 10319, and AASHTO M288 guarantees reliability and safety. Applications span roadway reinforcement, slope stabilization, drainage systems, and environmental protection, offering multifunctionality and long-term operational efficiency. Easy installation, dimensional stability, and eco-friendly material options enhance sustainability, making high-performance geotextiles an essential choice for modern engineering projects seeking strength, resilience, and longevity.