How to Choose Geomembrane

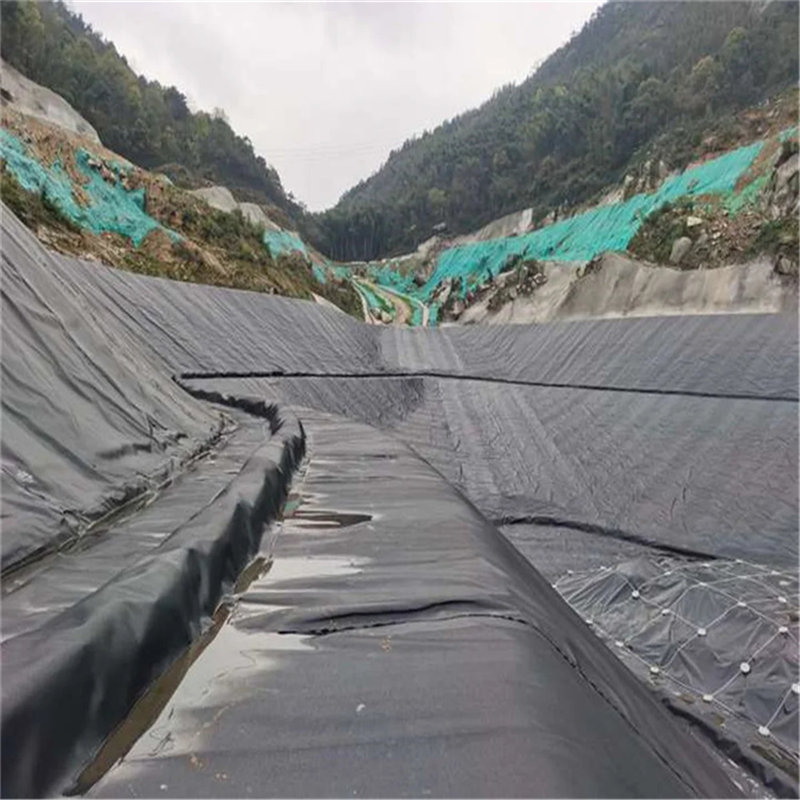

Choosing the right geomembrane is critical for the long-term success of projects involving environmental protection, waste containment, water reservoirs, and mining applications. If you’re wondering how to choose geomembrane, this guide is tailored to help you make a confident, cost-effective, and performance-driven decision.

Why Learning How to Choose Geomembrane Matters

Not all geomembranes are created equal. The wrong choice can lead to leaks, contamination, regulatory issues, and massive repair costs. Understanding how to choose geomembrane ensures you select a liner that performs reliably under the demands of your specific project — whether it’s for landfills, ponds, canals, or chemical containment.

Key Factors on How to Choose Geomembrane

Here’s everything you need to evaluate when deciding how to choose geomembrane:

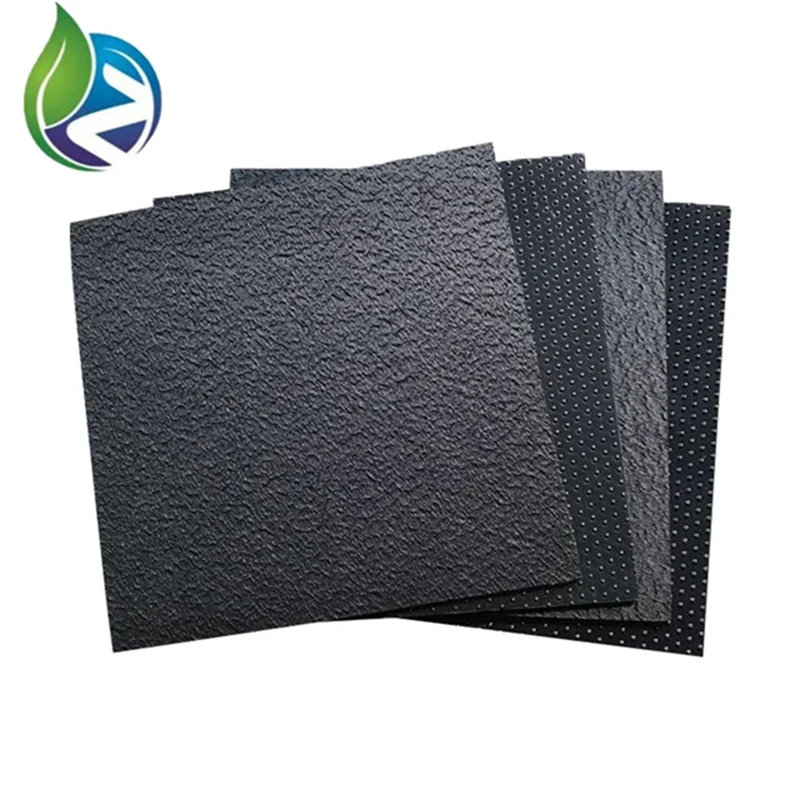

1. Material Type: HDPE, LDPE, LLDPE, PVC, or EVA?

HDPE Geomembrane: Best for durability, UV resistance, and chemical protection. Ideal for landfills and mining.

LDPE/LLDPE Geomembrane: Offers better flexibility, suited for uneven or irregular surfaces.

PVC Geomembrane: Soft and easy to install but less resistant to UV and chemicals.

EVA Geomembrane: Great for tunnels and subways due to high flexibility and elongation.

? If you’re unsure how to choose geomembrane material, consider environmental exposure, required lifespan, and mechanical stress.

2. Thickness Matters

The thickness of a geomembrane ranges from 0.5mm to 3mm. Here's how to choose:

0.75–1.0mm: Suitable for small ponds and temporary applications.

1.5mm: Standard for landfills, wastewater treatment, and reservoirs.

2.0–3.0mm: Recommended for mining, hazardous waste containment, and high-pressure environments.

? Tip: When thinking about how to choose geomembrane, balance project budget with performance requirements. Thicker doesn’t always mean better, but it often ensures safety.

3. Project Environment

You must assess the working conditions before deciding how to choose geomembrane:

UV exposure? → Use UV-stabilized HDPE.

Chemical exposure? → Use chemically resistant liners like HDPE or EVA.

Low-temperature area? → Choose materials with high flexibility and cold crack resistance.

4. Installation Method

When asking how to choose geomembrane, remember: installation affects performance.

Weldability: HDPE geomembranes are ideal for heat welding, creating leak-proof seams.

Flexibility: LLDPE and PVC are easier to handle on curved or uneven surfaces.

Choose geomembranes that match your team’s expertise and your site’s layout.

5. Certification & Quality Standards

Always check for:

ISO 9001 Quality Certification

GRI-GM13 Compliance (for HDPE)

CE Marking (if used in Europe)

? Knowing how to choose geomembrane means recognizing high standards that ensure long-term reliability.

Bonus Tips on How to Choose Geomembrane

✅ Request Samples & Data Sheets: Compare real-world performance

✅ Consult Experts: A professional supplier can provide valuable insights on how to choose geomembrane for your application

✅ Get a Soil & Site Report: Understand ground conditions before selecting material or thickness

✅ Factor in Transportation & Welding Costs: Not just the material price

Why Buyers Trust Us for Geomembrane Solutions

Still unsure how to choose geomembrane? Our team brings decades of experience delivering high-performance geomembranes for:

Waste management

Water reservoirs

Oil & gas containment

Infrastructure & transportation projects

We offer:

? Fast delivery worldwide

✅ Factory-direct pricing

? On-site technical support

? Lab-tested, certified materials

Ready to Choose the Right Geomembrane?

Now that you understand how to choose geomembrane, don’t leave your decision to guesswork. Contact us today for a free consultation, technical support, or custom pricing tailored to your project needs.

? Let’s ensure your next project is sealed for success!