HDPE Geomembrane Anti-seepage Engineering Solutions

HDPE Geomembrane Anti-seepage Engineering Solutions: The Key to Effective Water Containment

When it comes to water containment and environmental protection, HDPE geomembrane anti-seepage engineering solutions offer unparalleled performance. High-Density Polyethylene (HDPE) geomembranes are trusted worldwide for their durability, chemical resistance, and outstanding anti-seepage capabilities. As environmental regulations tighten and project requirements become more demanding, HDPE geomembrane anti-seepage engineering solutions stand out as the most reliable and cost-effective choice.

What Is HDPE Geomembrane?

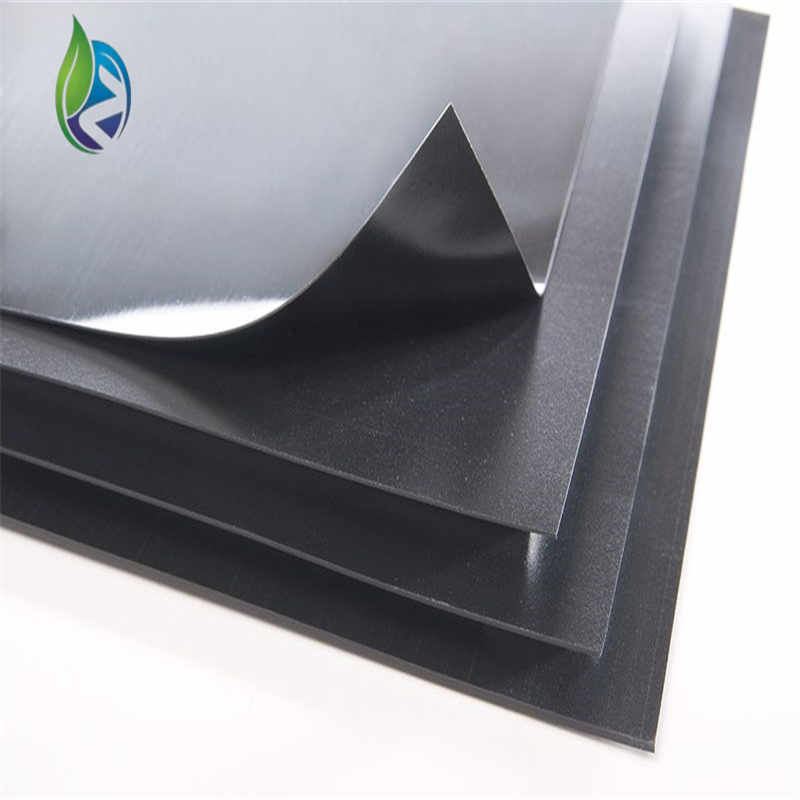

Before diving deeper into HDPE geomembrane anti-seepage engineering solutions, it’s essential to understand what HDPE geomembrane is. HDPE geomembrane is a synthetic liner made from high-density polyethylene resin. It is manufactured to provide a tough, flexible, and chemical-resistant barrier that prevents the movement of liquids and gases.

The properties that define HDPE geomembrane anti-seepage engineering solutions include excellent UV resistance, high tensile strength, and remarkable durability in aggressive environments.

Why Choose HDPE Geomembrane Anti-seepage Engineering Solutions?

There are several compelling reasons why industries worldwide choose HDPE geomembrane anti-seepage engineering solutions:

Superior Seepage Control: Prevents water infiltration and leakage in critical projects.

Chemical and UV Resistance: Ideal for harsh environments exposed to chemicals and sunlight.

Long-Term Durability: Service life can exceed 50 years under proper installation and conditions.

Flexible Installation: Available in various thicknesses and easily welded on-site.

Cost-Effective: Reduces maintenance and repair costs compared to traditional methods.

Every benefit underscores the value of HDPE geomembrane anti-seepage engineering solutions in safeguarding infrastructures and the environment.

Applications of HDPE Geomembrane Anti-seepage Engineering Solutions

The versatility of HDPE geomembrane anti-seepage engineering solutions makes them suitable for a wide range of industries, including:

Landfills: Serving as the primary liner to prevent leachate from contaminating groundwater.

Mining Operations: Lining tailing ponds, heap leach pads, and process water ponds.

Water Reservoirs and Canals: Ensuring water retention and minimizing losses due to seepage.

Wastewater Treatment Plants: Acting as a barrier for sludge and hazardous waste containment.

Agriculture: Lining irrigation ponds and biogas digesters for effective liquid containment.

Each application showcases the adaptability and critical importance of HDPE geomembrane anti-seepage engineering solutions.

How HDPE Geomembrane Anti-seepage Engineering Solutions Work

HDPE geomembrane anti-seepage engineering solutions function by creating an impermeable barrier that blocks the flow of liquids. Proper installation is crucial:

Surface Preparation: The subgrade is smoothed and compacted to prevent punctures.

Deployment: HDPE sheets are unrolled and positioned carefully to minimize wrinkles.

Seaming: Specialized welding techniques (hot wedge or extrusion welding) fuse the sheets, ensuring a leak-proof seam.

Testing: Non-destructive tests verify seam integrity, guaranteeing the effectiveness of HDPE geomembrane anti-seepage engineering solutions.

Attention to detail during installation ensures long-term performance and maximizes the benefits of the solution.

Advantages of HDPE Geomembrane Anti-seepage Engineering Solutions

Several key advantages distinguish HDPE geomembrane anti-seepage engineering solutions from other liner systems:

Environmental Protection: Prevents contamination of soil and groundwater.

Versatility: Suitable for both permanent and temporary containment projects.

Adaptability: Performs reliably under a wide range of temperatures and loading conditions.

Compliance: Helps meet local and international environmental regulations.

These advantages make HDPE geomembrane anti-seepage engineering solutions an essential choice for responsible project development.

Future Trends in HDPE Geomembrane Anti-seepage Engineering Solutions

The future of HDPE geomembrane anti-seepage engineering solutions looks bright, with innovations such as:

Smart Liners: Integrated sensors that monitor leakage in real-time.

Recycled HDPE Liners: Enhancing sustainability by incorporating recycled materials.

Enhanced Seaming Technologies: Making installations faster and more reliable.

Continuous improvement ensures that HDPE geomembrane anti-seepage engineering solutions will meet the evolving needs of modern engineering and environmental management.

Conclusion

In conclusion, HDPE geomembrane anti-seepage engineering solutions represent the gold standard for reliable, long-lasting, and environmentally responsible containment. Whether for landfill linings, mining operations, water reservoirs, or agricultural projects, investing in HDPE geomembrane anti-seepage engineering solutions is a smart decision for the future.

Selecting the right materials and experts to implement HDPE geomembrane anti-seepage engineering solutions ensures project success, environmental protection, and long-term savings.