HDPE Geomembrane: Product Advantages and Wide Applications in Engineering Projects

Product Definition

HDPE geomembrane is a high-performance impermeable synthetic liner manufactured from high density polyethylene resin. It is designed to provide long-term seepage control, chemical resistance, and structural reliability in civil, hydraulic, environmental, and industrial engineering projects.

Technical Parameters and Specifications

Engineering performance of HDPE geomembrane is defined by standardized physical, mechanical, and durability indicators suitable for large-scale infrastructure projects.

Raw material: High Density Polyethylene (HDPE)

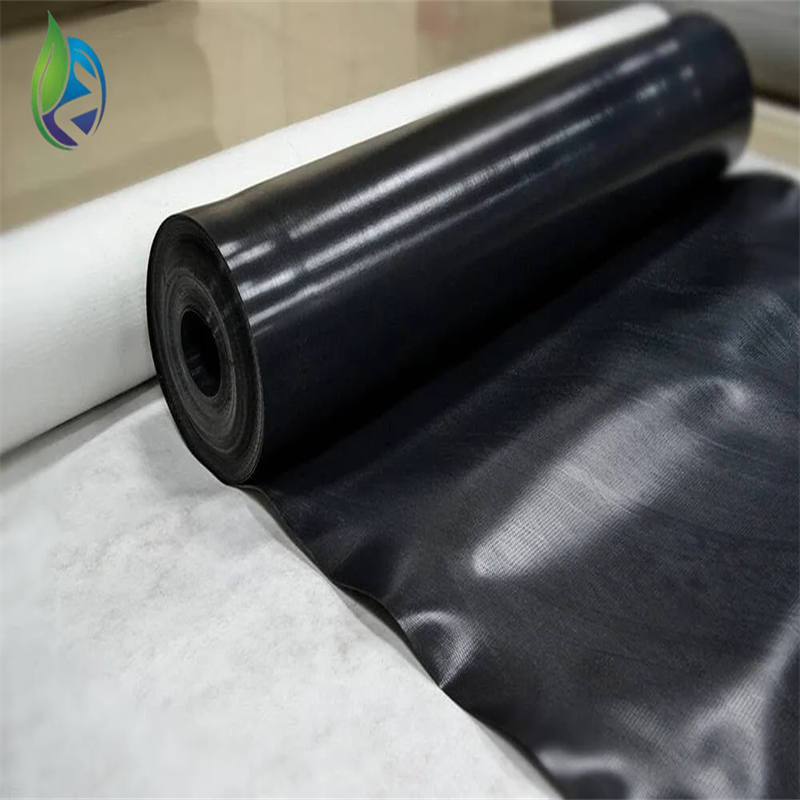

Standard thickness: 0.5 mm – 3.0 mm

Sheet width: 4.0 m – 8.0 m

Density: ≥0.94 g/cm³

Tensile strength at yield: ≥15 MPa

Elongation at break: ≥700%

Puncture resistance: ≥480 N

Carbon black content: 2.0%–3.0%

Oxidative induction time (OIT): ≥100 min

Service temperature range: -40°C to +60°C

Expected service life: 30–50 years (proper installation)

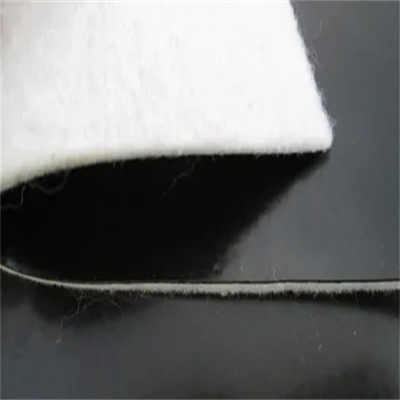

Structure and Material Composition

HDPE geomembrane is a homogeneous polymer sheet engineered for impermeability and durability.

Primary polymer matrix: High purity HDPE resin

Carbon black additive: UV resistance and aging protection

Antioxidants: Thermal and oxidative stability

Processing stabilizers: Ensure uniform melt flow and thickness

Manufacturing Process

Engineering-Oriented Production Steps

Raw HDPE resin selection and formulation control

High-temperature extrusion using flat-die or blown film lines

Sheet forming with automatic thickness calibration

Surface texturing (optional) for friction enhancement

Cooling, trimming, and roll winding

Quality inspection and laboratory testing

Core equipment: Extrusion lines, thickness scanners, tensile testers, carbon black dispersion analyzers.

Key process controls: Thickness tolerance, surface uniformity, additive dispersion, and thermal stability.

Industry Comparison

| Material | Impermeability | Chemical Resistance | Installation Efficiency | Lifecycle Cost |

|---|---|---|---|---|

| HDPE Geomembrane | Very High | Excellent | High | Low |

| LDPE Geomembrane | High | Good | High | Medium |

| Clay Liner | Medium | Low | Low | High |

| Concrete Lining | Medium | Medium | Low | High |

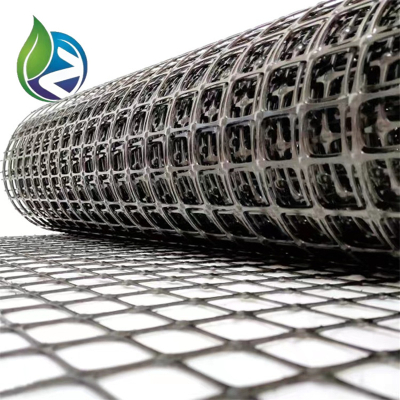

Wide Engineering Applications

HDPE geomembrane is widely applied across multiple engineering sectors due to its versatility and durability.

Water conservancy: Reservoirs, canals, dams, and irrigation systems

Environmental engineering: Landfills, leachate ponds, wastewater treatment

Mining projects: Heap leaching pads, tailings storage facilities

Aquaculture: Fish ponds and shrimp farming liners

Transportation: Tunnel waterproofing and subgrade protection

Core Pain Points and Engineering Solutions

Seepage losses: Continuous HDPE geomembrane provides near-zero permeability

Chemical corrosion: HDPE resists acids, alkalis, and salts

Structural deformation: High elongation accommodates settlement

Maintenance burden: Long service life reduces lifecycle maintenance costs

Risk Warnings and Mitigation Recommendations

Improper subgrade preparation can cause puncture risk

Unqualified welding may lead to leakage paths

Extended UV exposure before covering may accelerate aging

Inadequate anchoring can result in liner uplift

Procurement and Selection Guide

Define project application and hydraulic or environmental requirements

Select appropriate thickness based on pressure and load conditions

Determine smooth or textured surface requirements

Specify welding methods and seam testing standards

Verify compliance with ASTM, ISO, or EN standards

Evaluate supplier quality systems and project references

Plan logistics, installation schedule, and on-site handling

Engineering Case Example

In a municipal landfill expansion project, a 2.0 mm HDPE geomembrane was installed as the primary liner system over a compacted clay layer. The engineering plan included double-track hot wedge welding and 100% seam testing. Post-installation monitoring confirmed effective leachate containment and regulatory compliance.

FAQ

What is the main advantage of HDPE geomembrane? Excellent impermeability and durability.

Is HDPE geomembrane suitable for chemical exposure? Yes, it offers strong chemical resistance.

What thickness is commonly used? 1.0–2.0 mm for most engineering projects.

How are seams tested? Air pressure or vacuum box testing.

Can HDPE geomembrane handle settlement? Yes, due to high elongation.

Is UV resistance important? Yes, carbon black provides UV protection.

How long is the service life? Typically 30–50 years.

Can it be used underwater? Yes, for reservoirs and ponds.

Is third-party inspection recommended? Yes, for critical projects.

Does surface texture matter? Textured surfaces improve slope stability.

CTA

For project-specific HDPE geomembrane specifications, engineering drawings, pricing information, or material samples, please submit a formal request for quotation or technical documentation.

E-E-A-T Author Credentials

This article is prepared by a geosynthetics engineering specialist with over 15 years of experience in HDPE geomembrane design, manufacturing, and application across water conservancy, environmental protection, and mining infrastructure projects, supporting EPC contractors and global procurement teams.