Geotextile: Product Introduction and Key Advantages in Civil Engineering

Product Definition

Geotextile materials are permeable synthetic fabrics engineered for soil stabilization, separation, filtration, and drainage in civil engineering. They function as a structural interface between soil and aggregate layers, improving load distribution, controlling particle migration, and increasing long-term performance of infrastructure foundations.

Technical Parameters and Specifications

| Parameter | Typical Range | Test Method |

|---|---|---|

| Mass per Unit Area | 100–800 g/m² | ASTM D5261 |

| Tensile Strength (MD/CD) | 8–50 kN/m | ASTM D4595 |

| Elongation at Break | 15–80% | ASTM D4595 |

| CBR Puncture Resistance | 1.5–6.5 kN | ASTM D6241 |

| Apparent Opening Size (AOS) | 0.075–0.40 mm | ASTM D4751 |

| Permittivity | 0.3–2.0 s⁻¹ | ASTM D4491 |

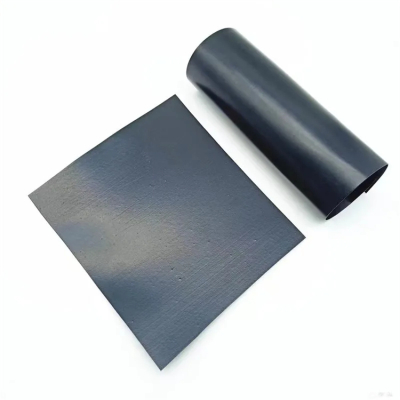

Structure and Material Composition

Base Polymer: Polypropylene (PP) or Polyester (PET)

Fabric Type: Woven or needle-punched nonwoven structure

Fiber Orientation: Cross-laid multidirectional network

Surface Treatment: Anti-UV and anti-oxidation additives

Pore Geometry: Controlled filtration openings

Manufacturing Process

Polymer drying and precision metering.

Melt extrusion through spinnerets to form continuous filaments.

Fiber drawing and controlled cooling.

Web formation via carding and cross-lapping equipment.

Needle punching using high-frequency loom systems.

Thermal bonding by calender rollers.

Quality control including tensile and thickness inspection.

Slitting, rolling, labeling, and moisture-protected packaging.

Industry Comparison

| Material Type | Separation Efficiency | Drainage Performance | Durability | Installation Complexity |

|---|---|---|---|---|

| Geotextile | High | High | Long-term | Low |

| Graded Sand Layer | Medium | Medium | Limited | High |

| Concrete Blinding | High | Low | Long-term | High |

| Bituminous Membrane | Low | Very Low | Medium | Medium |

Application Scenarios

Highway and expressway subgrade stabilization

Railway ballast separation layers

Port and airport pavement foundations

Landfill drainage and filtration systems

Retaining wall backfill reinforcement

Core Engineering Problems and Solutions

Problem: Soft foundation settlement

Solution: Geotextiles distribute stress and reduce differential deformation.Problem: Loss of aggregate into subgrade

Solution: Filtration and separation prevent fine migration.Problem: Water accumulation under pavements

Solution: Controlled permittivity ensures drainage paths.Problem: Construction access failure on weak soils

Solution: Creates stable working platforms for heavy equipment.

Risk Warnings and Mitigation Recommendations

Avoid installation on highly uneven or debris-contaminated surfaces.

Maintain minimum overlap widths to prevent seam failure.

Do not expose geotextiles to prolonged direct sunlight before covering.

Control vehicle traffic to avoid mechanical damage during base placement.

Procurement and Selection Guide

Conduct full geotechnical soil investigation and classification.

Define design traffic load and service life requirements.

Select fabric type (woven or nonwoven) based on function.

Match AOS values with soil particle size distribution.

Confirm tensile and puncture strength safety factors.

Request third-party laboratory test certificates.

Verify supplier manufacturing traceability and QA systems.

Engineering Case Study

In a coastal industrial park road project, needle-punched geotextiles were installed over soft silty clay before placing a 350 mm crushed stone layer. Field plate load tests recorded a 50% improvement in bearing capacity, while surface settlement remained below 12 mm after 18 months of service.

FAQ

Q1: How does geotextile improve subgrade strength?

A: By separating materials and distributing loads.Q2: Can geotextiles replace chemical soil stabilization?

A: They reduce the need but may not fully replace it.Q3: What is the difference between woven and nonwoven types?

A: Woven provides strength; nonwoven provides filtration.Q4: How long is the service life underground?

A: Typically 25–50 years.Q5: Are geotextiles resistant to biological degradation?

A: Yes, synthetic fibers are biologically stable.Q6: Can they be used in freezing climates?

A: Yes, when properly buried.Q7: What overlap width is recommended?

A: 300–500 mm depending on subgrade condition.Q8: Do they need anchoring?

A: Typically held in place by aggregate cover.Q9: How is quality verified on-site?

A: Visual checks and review of test reports.Q10: Can geotextiles work with geogrids?

A: Yes, composite systems are widely used.

CTA

For engineering projects and procurement planning, formal requests for quotation, detailed technical datasheets, and project-level samples can be submitted for professional evaluation and specification support.

E-E-A-T Author Credentials

This content is prepared by a civil engineering specialist with over 15 years of experience in ground improvement, soil stabilization systems, and infrastructure material specification,参与多条高速公路与工业园区基础工程的技术评审与标准制定工作。