Effective Methods for Subgrade Crack Resistance: Geogrid Shows Its Effectiveness

Folks in road or infrastructure work know exactly how big a headache cracked roadbeds are. And it’s not just tiny cracks, either—ones that get bigger over time, letting water seep in and wreck the whole setup. Before you know it, there are potholes, bumpy pavement, and costly repairs that shut roads down for days. Serious pain, that is—total hassle. For years, crews tried all sorts of fixes: more gravel, thicker asphalt, even extra layers of concrete. But none of those stuck. Cracks just keep coming back—keep on coming, no matter what—especially in spots with heavy traffic or tricky soil. That’s where geogrid material steps in, changing how roadbed reinforcement gets done and making those annoying, persistent cracks a thing of the past.

Why Roadbeds Crack (And Why It Matters)

Roadbeds crack for way more reasons than just heavy trucks, y’know? Start with the soil underneath—if it’s loose, or shifts when it rains or temperatures swing, the road above can’t stay stable. When it rains, water soaks into the soil, turning it soft and liable to sink. Then winter hits: that water freezes, expands, pushes the roadbed up. Then when it thaws? The soil shrinks, leaves gaps. Over time, those cycles pile on stress—stress that turns into cracks. Heavy traffic makes it worse, too: every time a truck rolls over, it presses down on the same spots, wearing away the roadbed’s strength little by little. Even small cracks are bad news, see? They let more water in, start a cycle that leads to way bigger damage. Repairs here are tricky, too—patching a crack might fix it for a few months, but the root issue? Unstable soil, uneven pressure? Still there. Geogrid material fixes that root cause by adding a support layer. It holds the soil in place, spreads out pressure—stops cracks before they even start. It’s not just a quick fix; it’s a way to make roadbeds sturdier from the get-go.

How Geogrid Material Stops Cracks in Their Tracks

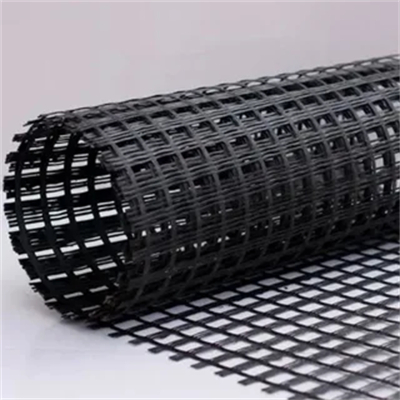

Geogrid material works a bit like a hidden support net under the roadbed. It’s made from strong, flexible stuff—usually polypropylene or polyester—stuff that can take tension without snapping. When laid under the roadbed, it locks into the surrounding soil, creating a bond that keeps the soil from shifting. And here’s the key: when the road takes a heavy load (like a big truck) or the soil tries to move, the geogrid spreads that pressure out. Doesn’t let it pile up in one spot. ’Cause concentrated pressure’s what causes cracks—if all the weight pushes down on a small area, the roadbed can’t handle it, splits right open. But with geogrid material? That weight gets spread across a wider area. No single spot takes too much stress. It helps with water damage, too: keeps the soil compact, in place, cuts down on gaps where water can seep in. Even if some water gets through, the geogrid keeps the soil from washing away or shrinking too much. Unlike rigid materials—they crack themselves under stress—geogrid material’s flexible. Moves a little with the soil, so it don’t add extra pressure. That flexibility’s why it works so well in spots with freeze-thaw cycles or loose soil; adapts to the conditions instead of fighting ’em.

The Big Advantages of Using Geogrid Material

Geogrid material ain’t just good at stopping cracks—it’s got a bunch of other perks that make it a go-to for infrastructure jobs. First off? It’s tough as nails. Unlike other reinforcement stuff—wood rots, metal rusts, y’know?—geogrid material holds up against water, chemicals, all that weather junk. Don’t fade in the sun, bugs don’t eat it, stands up to road salt in winter. That means it lasts for decades. Roadbeds stay strong longer, no need for constant repairs. And here’s another plus: it’s easy to work with. Comes in rolls, so crews can lay it out fast—no need for heavy gear to cut or shape it. Lightweight, too—makes transporting it easier, cuts labor costs. Geogrid material works in all kinds of spots, too. Works with every soil type—clay, sand, gravel—useful in almost any location. It even cuts down on other materials needed: with geogrid support, less gravel or asphalt gets used. Saves money, speeds up construction. And since it stops cracks from forming? Fewer road closures for repairs. Good for commuters, good for businesses that rely on smooth traffic. All these advantages add up to a solution that’s not just effective—it’s cheap long-term, too.

Where Geogrid Material Makes the Biggest Difference

Geogrid material ain’t just for highways, either—it works in all sorts of infrastructure projects where roadbeds or foundations need reinforcement. Highways and major roads? Obviously a big one—they handle the most traffic, highest crack risk. But rural roads benefit too; they usually have looser soil and less regular upkeep, so heavy gear passing through won’t crack the roadbed like it used to. Industrial yards are another spot where it shines—places where trucks carrying heavy materials drive around all day. Constant pressure would wear out a regular roadbed fast, but geogrid material adds the support needed to keep it intact. Even smaller projects get a boost: parking lots, access roads for neighborhoods. These spots might not have as much traffic as highways, but they still deal with weather damage and occasional heavy vehicles. Geogrid material here keeps the pavement smooth, crack-free, makes the space safer, nicer to look at. It even works in non-road projects—retaining walls, embankments—anywhere soil stability’s key to preventing cracks or collapse. No matter the project, geogrid material adds a protection layer that makes the structure last longer.

Installing Geogrid Material: Simple, But Effective

Installing geogrid material don’t need crazy fancy gear, but it does need careful prep work to make sure it works right. First, crews prep the area—clear out any debris, level the soil, compact it as much as possible. Compacted soil’s important, y’know? Gives the geogrid a stable base to lock into. Then the geogrid material gets unrolled over the area. Laid flat, each roll overlapping a few inches—gotta make sure there are no gaps, ’cause gaps would be weak spots where cracks could start. Once laid out, crews secure it to the soil with stakes or pins—especially along the edges, to keep it from shifting during the next steps. After that, the top layer goes on—usually gravel, sand, or asphalt. As that top layer gets compacted, it presses the geogrid into the soil below, creating a tight bond. That bond’s what lets the geogrid spread out pressure later. The best part? The installation process don’t add much time to the project. Compared to laying extra layers of concrete or gravel, rolling out geogrid material is fast—keeps the project on schedule. And crews don’t need no fancy training, either—most folks who work on road projects can learn to install it quick. Once it’s down, there’s not much maintenance needed; the geogrid stays in place, working quiet-like under the roadbed for years.

The Future of Roadbed Reinforcement: Geogrid Material Leads the Way

These days, cities and towns wanna build infrastructure that lasts longer, needs less maintenance—and geogrid material’s getting more common ’cause of that. Real talk—the big reason? It saves money long-term. Even though there’s an upfront cost for the geogrid, the money saved on repairs and road closures later makes it worth it. Say, a road with geogrid material might last 10-15 years longer than one without it. That’s a decade of no major crack repairs, adds up to big savings. More projects are focusing on being easier on the planet, too—and geogrid material fits right in. Since it’s made from recycled stuff (many geogrids use recycled plastics) and cuts down on other materials needed, it ain’t so hard on the environment. It also cuts down on waste from repairs—fewer cracks mean fewer patches, less material ends up in landfills. As technology gets better, geogrid material’s improving, too. New versions are stronger, more flexible, work in even harsher conditions—spots with extreme heat, heavy rain. Some are even designed to let water drain better, cutting down on water damage even more. It’s clear geogrid material ain’t just a trend—it’s a key part of infrastructure’s future, helping build roads that are stronger, more durable, easier to maintain.

Why Geogrid Material Is the Smart Choice for Crack-Free Roadbeds

At the end of the day, geogrid material’s all about solving a common problem in a simple, effective way. Roadbed cracks? Inevitable with traditional methods, but they don’t have to be. Geogrid material adds that extra support layer, fixes the root causes of cracking—unstable soil, uneven pressure, water damage—don’t just treat the symptoms. It’s tough enough to last decades, easy enough to install without slowing projects down, works in almost any location. For infrastructure crews? Means fewer headaches, lower long-term costs. For commuters and businesses? Smoother roads, fewer closures, a more reliable transportation network. For the environment? Less waste, smaller carbon footprint from construction and repairs. When you look at all those benefits? No wonder geogrid material’s becoming the go-to solution for folks who wanna build crack-free roadbeds. It’s not just a material—it’s a smarter way to build infrastructure that works better, lasts longer.

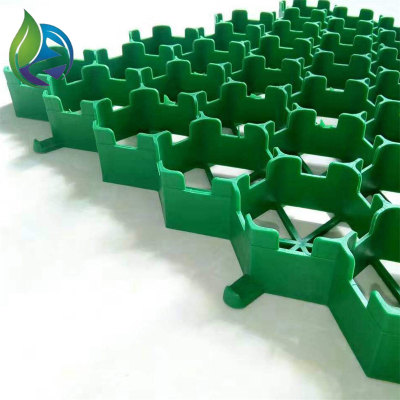

pavers plastic is affordable and easy to install. So pretty much anyone can use ’em—big companies, small homeowners, whoever. It lasts for years too, so the money spent on it pays off long-term. Whether cooling a lot, cutting down on runoff, or just adding a bit of green to a hard area, grass pavers plastic delivers. It’s not just a good idea on paper—it works in real life. Turns dull, lifeless hard spaces into places that are good for people and the planet. As more cities and communities start using grass pavers plastic, a shift toward more sustainable urban areas will probably happen—places where concrete and greenery work together, not against each other. Folks who care about making cities healthier and more livable? Grass pavers plastic is a step in the right direction.