Geotextile "blessing"! New guarantee for road anti-subsidence

Geotextile Fabric Gets the Job Done! Here’s How to Keep Roads from Settling

Road settlement isn’t just a minor hassle for infrastructure crews. It’s a long-term headache—slowly chipping away at safety, driving up maintenance costs, and ruining daily commutes. Even a brand-new road can develop tiny cracks or dips in just a year. Over time, those turn into potholes, bumpy stretches, and even sunken spots that scratch car undercarriages.

Cities and transportation teams have to pull money from important projects to fix this—like repairing old bridges or adding bike lanes communities asked for. Then lanes close, and traffic backs up for miles. Commuters who need smooth roads for work, school, or doctor’s visits end up frustrated. It’s such a pain.

Road settlement happens for simple reasons. The soil under the road base might be weak, unable to hold weight. Rainwater soaks in and washes away the material that supports the road. Heavy trucks press down on the soil day after day, compressing it over months. For years, crews used old fixes—laying thicker gravel or using machines to compact the soil tighter. But these band-aids don’t last. That’s where geotextile fabric comes in. It’s simple, no extra bells and whistles, and works like a charm. It changes how we protect roads from sinking, makes infrastructure more durable, and saves a ton on long-term maintenance.

Road Settlement’s Main Issues: Why Old Fixes Fall Short

To get why geotextile fabric works so well, start with what makes roads settle. Most roads have three layers: the top (asphalt or concrete), the middle (gravel or crushed stone—called the “base course”), and the bottom (native soil).

Roads stay steady only when the soil and base course work together to support vehicles. Soft, wet, or poorly compacted soil can’t handle the weight. Over time, the soil compresses more, the base course shifts, and the road sinks. This happens on most projects.

Water makes it worse. Rain or groundwater soaks into the soil, weakening its structure. Clay soils swell when wet and shrink when dry—leaving gaps that let the base course slide. Sandy soils wash away completely if water flows through, creating empty holes under the road. How can the road not sink?

Old fixes sound okay, but you run into problems when you’re actually on the job. Take extra gravel, for example—it adds weight, makes materials cost more, and slows down construction. Drainage pipes help with water, but here’s the catch: they don’t stop soil from shifting or compressing. They’re just temporary patches, not real solutions.

Heavy traffic is another big problem. Highways and busy city roads see hundreds of heavy trucks every single day. Those wheels keep pressing down—after a few months, the soil and gravel layer compact and sink. Stronger base materials help, but without something to hold the layers in place, the material mixes with soil or slides out. Geotextile fabric fixes this. It acts as both a barrier and a strengthener, keeping layers separate and making soil tough enough to handle more weight without settling.

How Geotextile Fabric Works: Simple Science for Stronger Roads

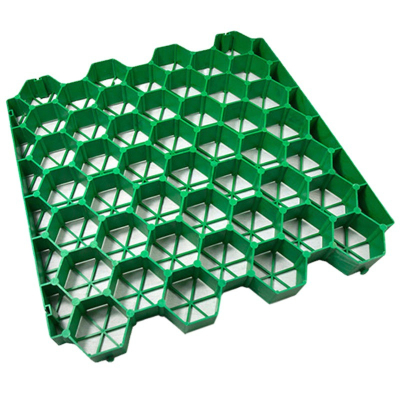

Geotextile fabric isn’t a fancy gadget. It works because it’s straightforward. Made from synthetic fibers (polyester, polypropylene), it’s built to resist water, chemicals, and heavy use.

Unlike plastic sheeting—plastic traps water and makes soil problems worse—geotextile fabric lets water drain through while keeping soil and gravel layers apart. This two-in-one job—separating layers and filtering water—makes it perfect for road projects.

First, separating layers: the base course (gravel) and native soil need to stay apart. If they mix, gravel loses its support strength and soil gets shakier. Geotextile fabric laid between them blocks small soil bits from moving up into the gravel and stops gravel from sinking into the soil. Both layers stay intact: gravel stays strong, and soil stays put without being compressed.

Next, filtering water: water seeping through the road into the gravel layer needs to drain without carrying soil along. The fabric’s tiny pores let water pass but trap soil particles. This prevents erosion and gaps under the road, keeping soil structure strong and cutting down on water-related settlement.

Strengthening is another big plus. Woven geotextile has great pull strength—it barely stretches when pressed. Lay it in the road base, and it adds extra support for heavy traffic, keeping the gravel layer from shifting. For roads with heavy loads, it spreads weight evenly across the soil, avoiding over-compression and sinking.

Best of all, geotextile fabric doesn’t replace old materials. It just makes them work better. It teams up with gravel, soil, and asphalt to strengthen the whole road structure—no extra weight or complicated steps. It’s super lightweight: two guys can carry a roll, unroll it in minutes, and nail it down—no heavy machinery needed. It doesn’t hold up construction at all, unlike hauling and spreading extra gravel, which takes hours with loaders and compactors. Time is money on job sites, so that’s a huge win.

Geotextile Fabric in Action: It Works for Every Road Type

Geotextile works for just about every road type—busy city streets, quiet country roads, even highways with tons of heavy trucks. You just need to pick the right fabric (woven vs. non-woven) for the job.

Let’s start with city main roads: cars and trucks nonstop, soil shaken up from old construction. That soil settles fast, so woven geotextile is perfect. It’s tight, strong, and helps drain water—critical in cities where rain pools quick and soaks the ground. Good drainage keeps soil dry and gravel intact, so the road lasts longer and needs fewer repairs.

Rural roads are different—less heavy traffic, but the soil’s mostly soft, organic stuff with lots of clay or silt. This soil swells when wet and shrinks when dry, causing cracks or settlement. Non-woven geotextile is the way to go here. It’s thicker, soaks up a little moisture, and keeps the soil from getting too dry or too wet. It adds gentle reinforcement to hold the gravel layer in place without being rigid—perfect for roads that don’t need constant heavy-load support. I’ve seen plenty of rural jobs where crews swear by this stuff—it’s way less trouble than piling on extra gravel.

Highways need to last decades and handle thousands of heavy trucks a day. The soil under highways is more compacted, but settlement still happens. Crews usually mix woven and non-woven fabric: woven for strength to handle truck traffic, non-woven for filtration and soil stability. This mix keeps highways smooth and safe for years, avoiding costly resurfacing or lane closures that mess up commutes.

Even temporary roads—construction sites, emergency access—benefit. They need fast installation and strength for heavy equipment, but not long-term durability. Geotextile lets crews use less gravel (saving time and money) while still supporting heavy loads. And you can reuse the fabric after the project—kinder to the planet, too.

Why Geotextile Fabric Beats Old Methods: Cost, Longevity, and Eco-Friendliness

A lot of people ask why we can’t just stick with old methods like thicker gravel or more compaction. The answer comes down to three simple things: cost, how long it lasts, and being kind to the environment. Geotextile beats old ways in all three.

Cost: Old settlement fixes use tons of gravel or stone. Gravel is heavy—hauling it costs more because you need extra fuel. Installing it takes more time and workers to spread and compact thick layers. Geotextile is lightweight: one roll covers a huge area, and a small crew can get it down fast. Using less gravel saves money on materials, transport, and labor. Of course, if you’re working in a remote area where gravel is cheap to haul, you might not save much upfront. But over the road’s life? Fewer potholes, less resurfacing—those savings add up fast. For teams with tight budgets, that’s a huge relief.

Longevity: Old methods keep roads stable for 5–10 years. Geotextile extends that to 15–20 years or more. It fixes the real reasons roads settle—soil mixing, water erosion, uneven weight—instead of just covering up the problem. Roads with only gravel settle within years as soil mixes in. Geotextile keeps layers separate, so the gravel layer stays strong. This durability matters most in harsh weather—heavy rain or freezing temps speed up water damage, but geotextile resists that.

Eco-friendliness: Today’s infrastructure work tries to hurt the environment less, and geotextile fits right in. A lot of it’s made from recycled synthetic materials, so it cuts down on waste and keeps plastic out of landfills. It also uses less gravel—gravel is non-renewable, and mining it harms ecosystems. Less gravel means a smaller carbon footprint. And since the road lasts longer, there’s less future construction—even less environmental harm. It’s good for the planet and good for budgets.

The Future of Road Building: Geotextile Fabric as a Regular Practice

Infrastructure teams everywhere want roads that are stronger, cheaper, and more eco-friendly. Geotextile is fast becoming a regular part of road building—it’s no longer an “extra.” It’s a must-have to avoid settlement headaches.

Manufacturers are making geotextile better these days. It’s stronger, more resistant to chemicals and UV rays, and better at filtering water. Some even make biodegradable fabric—perfect for temporary roads or sensitive environments. These improvements let geotextile handle trickier jobs: roads in extreme heat or cold, roads built on super soft soil—making it more versatile than ever.

Smaller towns and cities are catching on too. Once used mostly for big highways, geotextile is now common for local roads. Small communities have realized the upfront cost of fabric is way lower than fixing a settled road in a few years. For tight budgets, this is a game-changer—roads last longer without overspending, cutting constant repair costs.

Fabric makers and infrastructure engineers are working together more now, too. Engineers help design fabrics for specific projects, and makers use that feedback to improve their products. This partnership creates more useful, project-specific fabrics that solve real job-site problems—not generic ones that don’t fit right.

Road settlement has been a headache for infrastructure crews for decades, but geotextile fabric has turned things around. It acts as a barrier, filter, and strengthener all in one—keeping layers separate, stopping erosion, and spreading weight evenly. It’s lightweight, easy to install, and affordable, and it adapts to any road type—busy city streets, rural roads, highways—to make them stronger and more durable.Geotextile solves multiple problems at once: cuts construction costs, means fewer repairs, and is kinder to the environment. For crews, that means fewer headaches and more time to focus on other projects. For commuters, it means smoother, safer roads—no swerving around potholes or being late because of road work.As road building evolves, geotextile will only grow more important. It’s a simple solution to a complex problem—one that builds roads that last. For anyone in infrastructure—engineers, crews, commuters—it’s more than a material. It’s a new guarantee that roads stay strong, safe, and reliable for years. And here’s a final tip for crews: don’t just grab the cheapest fabric. Match it to the job—non-woven for clay-heavy rural soil, woven for high-traffic city streets, and a mix for highways. Pick right, and you’ll see the difference. The industry can’t afford to skip this better approach.