Drainage board construction scheme

Drainage Board Construction Scheme: A Complete Guide to Efficient Groundwater Management

The drainage board construction scheme plays a pivotal role in modern civil engineering projects. Whether it’s for building foundations, tunnels, green roofs, or roadbeds, a well-designed drainage board construction scheme ensures structural stability by effectively managing subsurface water. In this article, we will detail the components, steps, benefits, and best practices involved in a professional drainage board construction scheme—offering the insights you need to implement high-performance waterproofing and drainage systems.

What Is a Drainage Board?

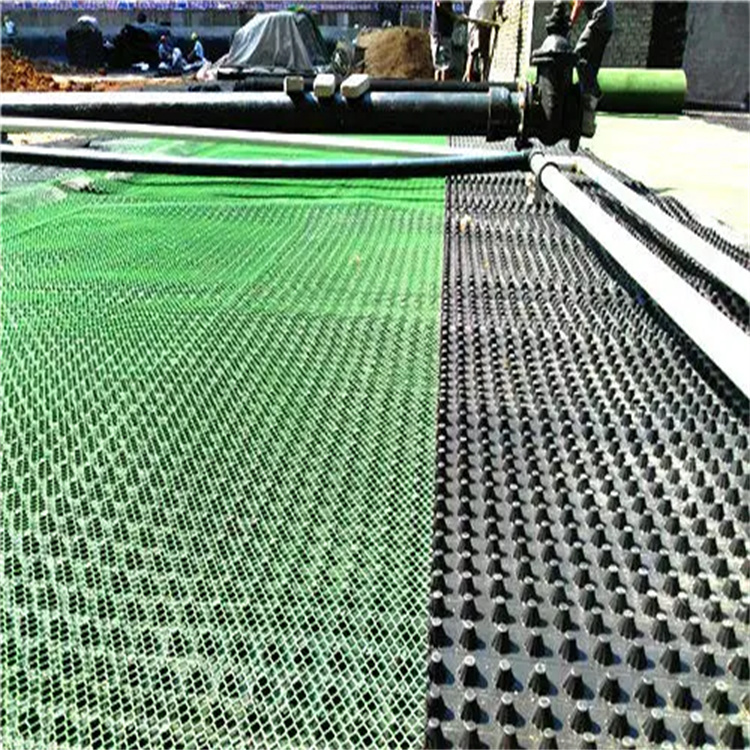

Before diving into the drainage board construction scheme, it's important to understand what a drainage board is. A drainage board is a high-density plastic or composite panel, usually designed with dimples, channels, or holes, to facilitate the rapid discharge of water. It's often used behind retaining walls, beneath basement floors, under green roof systems, and in roadway subgrades.

The drainage board construction scheme relies on these materials to efficiently redirect water away from structures, preventing hydrostatic pressure buildup, erosion, and water damage.

Key Components of a Drainage Board Construction Scheme

A standard drainage board construction scheme includes the following layers and materials:

Waterproof Membrane: Protects the structural base from water ingress.

Drainage Board: Provides a path for water to flow vertically or horizontally.

Filter Fabric (Geotextile Layer): Prevents soil and sediment from clogging the drainage system.

Backfill Material: Supports the board while allowing free water flow.

Discharge Outlet/Pipe: Channels collected water away from the site.

The effectiveness of any drainage board construction scheme depends on the precise integration of these elements.

Step-by-Step Drainage Board Construction Scheme

To ensure optimal drainage and long-term performance, follow this professional drainage board construction scheme:

Step 1: Site Preparation

Clear vegetation, debris, and sharp rocks.

Ensure a smooth and compact surface.

Mark water flow directions and discharge points.

Step 2: Install Waterproofing Membrane

Apply a liquid or sheet membrane directly onto concrete or other structural surfaces.

Ensure full coverage and proper curing if using a liquid system.

Step 3: Drainage Board Installation

Roll or place drainage boards vertically against the wall or horizontally over the slab.

Ensure tight seams between panels to avoid leakage.

Secure using plastic nails or adhesive suitable for the substrate.

Step 4: Geotextile Layer Application

Overlay a geotextile fabric on the exposed side of the board.

This acts as a filtration barrier, preventing soil from blocking the flow channels.

Step 5: Backfilling

Backfill using coarse gravel, sand, or engineered fill to support the system.

Avoid sharp or compacting backfill materials that can damage the drainage board.

Step 6: Outlet Connection

Direct the base of the drainage board to a perforated pipe or a designated drainage outlet.

Make sure water exits at a lower elevation to prevent backup.

Each phase of the drainage board construction scheme must be executed with precision to prevent future failures.

Advantages of a Well-Designed Drainage Board Construction Scheme

A well-implemented drainage board construction scheme offers multiple engineering and environmental benefits:

✅ Prevents Hydrostatic Pressure

Helps avoid water pressure buildup behind walls or slabs.✅ Improves Waterproofing Performance

Extends the life of membranes by keeping water away from critical surfaces.✅ Controls Erosion

Directs water flow to safe discharge points, reducing surface washout.✅ Promotes Soil Stability

Keeps foundations stable even during heavy rainfall or flooding.✅ Reduces Maintenance Costs

Minimizes water-related damage, which can be costly to repair long term.

Applications of Drainage Board Construction Scheme

The drainage board construction scheme is suitable for a wide range of civil and landscape engineering scenarios:

? Underground Garages and Basements

? Retaining Walls

? Green Roofs and Podiums

? Roadbeds and Tunnels

? High-Rise Foundations

In each of these cases, a reliable drainage board construction scheme ensures efficient water discharge and prevents premature structural failure.

Best Practices and Tips

To ensure the success of your drainage board construction scheme, consider these expert recommendations:

✅ Always match drainage board thickness and compressive strength with project demands.

✅ Overlap geotextile layers by at least 100mm to prevent soil intrusion.

✅ Use a slope of at least 1% toward the outlet for efficient water flow.

✅ Inspect joints regularly and repair any dislodged panels during backfill.

✅ Keep an as-built record of the drainage board construction scheme layout for maintenance and upgrades.

Conclusion

A well-engineered drainage board construction scheme is the backbone of water management in modern infrastructure. By understanding the materials, installation steps, and performance benefits, you can design systems that protect your project against water infiltration, erosion, and foundation failure. Whether you're working on residential basements or industrial retaining walls, a thoughtfully executed drainage board construction scheme guarantees longevity, stability, and peace of mind.

This is a detailed introduction to the construction process of drainage boards. During construction, strictly follow the process to ensure quality and effectiveness. Additionally, pay attention to safety measures to protect workers' well-being. If any issues arise during construction, address them promptly to ensure a smooth process. Finally, conduct a quality inspection of the completed drainage boards to ensure they meet requirements, thereby providing assurance for the successful completion of the project.