The Difference Between Fiber Glass Geogrid and Steel-Plastic Geogrid

The Difference Between Fiber Glass Geogrid and Steel-Plastic Geogrid

In the field of modern civil engineering and infrastructure reinforcement, the difference between fiber glass geogrid and steel-plastic geogrid is a topic of critical importance. Engineers, contractors, and project managers must understand these differences to choose the right material for road stabilization, soil reinforcement, and slope protection applications.

This article breaks down the difference between fiber glass geogrid and steel-plastic geogrid, comparing their materials, mechanical properties, usage scenarios, benefits, and limitations.

What Is a Fiber Glass Geogrid?

Fiber glass geogrid is a geosynthetic material made from alkali-free glass fibers. These fibers are coated with a bitumen or polymer material to enhance bonding and resist environmental degradation. The primary function of a fiber glass geogrid is to reinforce asphalt pavements and prevent reflective cracking.

When discussing the difference between fiber glass geogrid and steel-plastic geogrid, it’s essential to note that fiber glass geogrids are non-metallic, corrosion-resistant, and exhibit high tensile strength in both longitudinal and transverse directions.

What Is a Steel-Plastic Geogrid?

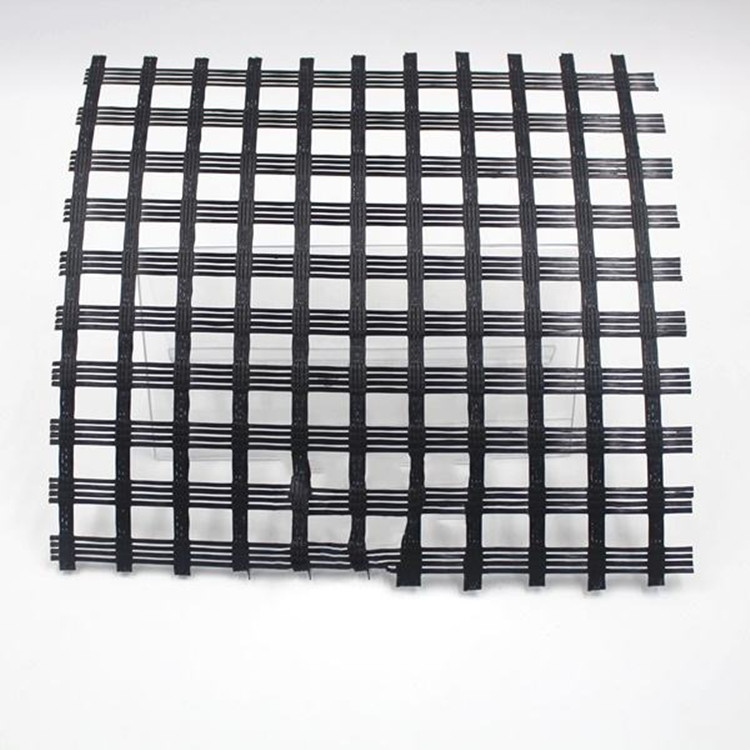

Steel-plastic geogrid consists of high-tensile steel wires encased within a polyethylene or polypropylene plastic sheath. It combines the structural integrity of steel with the flexibility and corrosion protection of plastic.

Understanding the difference between fiber glass geogrid and steel-plastic geogrid involves recognizing that steel-plastic geogrids are generally used for soft foundation reinforcement, retaining walls, and embankment slope stabilization due to their superior load-bearing capacity and long-term performance.

The Difference Between Fiber Glass Geogrid and Steel-Plastic Geogrid: A Detailed Comparison

| Criteria | Fiber Glass Geogrid | Steel-Plastic Geogrid |

|---|---|---|

| Material Composition | Alkali-free glass fibers with polymer coating | High-strength steel wires wrapped in plastic |

| Tensile Strength | Moderate to high | Very high |

| Corrosion Resistance | Excellent (non-metallic) | Good (protected by plastic coating) |

| Thermal Stability | High (resistant to high asphalt laying temperatures) | Moderate |

| Flexibility | High | Moderate |

| Best Applications | Asphalt pavement reinforcement, airport runways | Retaining walls, mining roads, weak soil stabilization |

| Installation Simplicity | Lightweight and easy to install | Heavier, may require more labor/equipment |

| Durability in Acidic/Alkaline Soil | Excellent | Good but depends on coating quality |

The table above highlights the difference between fiber glass geogrid and steel-plastic geogrid, showing their varied strengths depending on the engineering need.

Key Benefits of Fiber Glass Geogrid

Superior Crack Resistance: Especially effective in reducing reflective cracking in pavement overlays.

Thermal Stability: Maintains structure under high temperatures from hot-mix asphalt.

Chemical Resistance: Resists oxidation and degradation in harsh environments.

Ease of Use: Lightweight and flexible, making transport and installation more convenient.

Understanding the difference between fiber glass geogrid and steel-plastic geogrid shows that fiber glass options are ideal when dealing with surface-level pavement projects.

Key Benefits of Steel-Plastic Geogrid

High Load-Bearing Capacity: Perfect for applications involving heavy loads or vehicular pressure.

Reinforcement Strength: Provides excellent structural integrity in deep subgrade reinforcement.

Environmental Adaptability: Performs well in environments with fluctuating pH levels and moisture.

Long Service Life: The combination of steel and plastic offers long-term durability under stress.

This again reflects the difference between fiber glass geogrid and steel-plastic geogrid when heavier and more structural demands are present.

Which One Should You Choose?

Choosing between fiber glass and steel-plastic geogrid depends on several factors:

Project Type: Asphalt overlays prefer fiber glass; foundation and subgrade projects lean toward steel-plastic.

Load Requirements: For heavy industrial or mining roads, steel-plastic geogrid is more suitable.

Environmental Conditions: High-heat or chemically aggressive environments might benefit more from fiber glass.

Budget & Installation: Fiber glass tends to be more cost-effective and easier to install.

Understanding the difference between fiber glass geogrid and steel-plastic geogrid ensures optimal material performance and project efficiency.

Conclusion

In summary, the difference between fiber glass geogrid and steel-plastic geogrid lies in their composition, mechanical performance, and ideal usage scenarios. Fiber glass geogrid excels in asphalt reinforcement due to its thermal stability and anti-cracking properties, while steel-plastic geogrid offers unmatched strength for subgrade and slope reinforcement in demanding environments.

Selecting the correct geogrid requires a full understanding of site conditions, expected loads, and long-term performance goals. With a clear grasp of the difference between fiber glass geogrid and steel-plastic geogrid, engineers and contractors can achieve more stable, cost-efficient, and durable construction outcomes.