Geomembrane for Construction Engineering

Manufacturing Process

Standardized engineering production workflow:

Raw Material Dosing: Virgin HDPE/LLDPE resin with antioxidant and carbon black masterbatch

Drying and Conditioning: Hopper drying to maintain moisture below technical thresholds

Flat Die Extrusion: Multi-zone heating system controlled between 180–220°C

Sheet Forming: Precision calendering for thickness control

Surface Texturing: Embossing rollers for friction optimization

Automatic Cooling: Water-cooled conveyor stabilization

Inline Monitoring: Laser thickness gauges and spark testing equipment

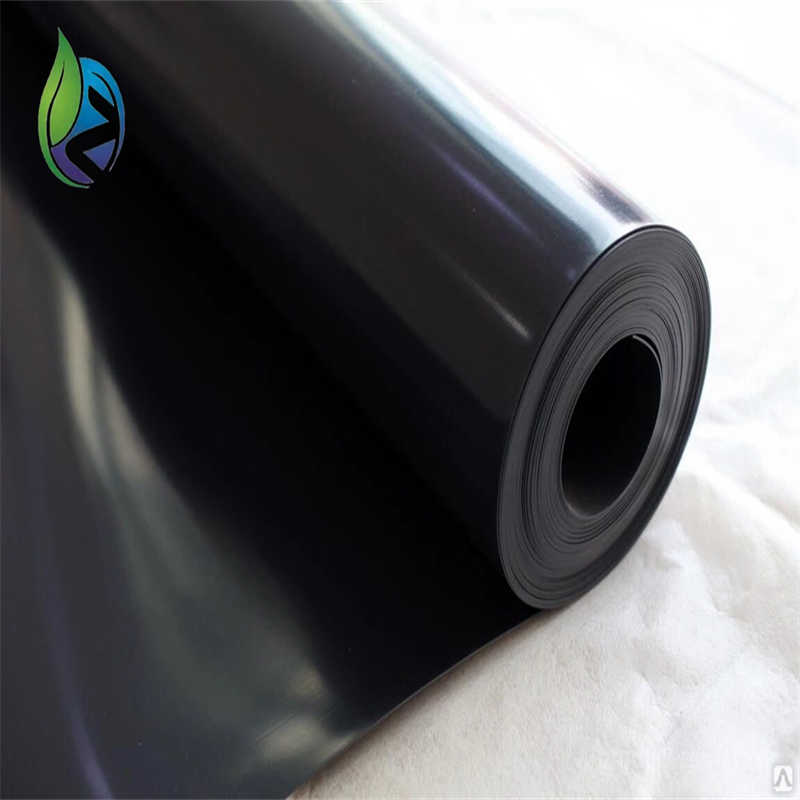

Final Winding: Tension-controlled automatic roll systems

Product Definition

The Geomembrane for Construction Engineering is an impermeable polymeric barrier sheet designed to control fluid migration in civil, hydraulic, and structural projects. It provides long-term leakage prevention, chemical resistance, and mechanical stability for foundations, tunnels, basements, and infrastructure containment systems.

Technical Parameters and Specifications

Key engineering specifications aligned with international construction practices:

Nominal Thickness: 0.5 mm, 0.75 mm, 1.0 mm, 1.5 mm, 2.0 mm

Sheet Width: 5.0–8.0 m

Roll Length: 50–200 m

Density: ≥ 0.94 g/cm³ (HDPE grades)

Tensile Strength at Yield: ≥ 14–20 kN/m (depending on thickness)

Elongation at Break: ≥ 700%

Puncture Resistance (CBR): ≥ 1.6–4.0 kN

Carbon Black Content: 2.0–3.0%

Service Temperature: -40°C to +60°C

Permeability Coefficient: ≤ 1.0 × 10⁻¹³ m/s

Structure and Material Composition

Typical engineered layer structure:

Upper Functional Layer: UV-stabilized smooth or textured polymer surface

Core Barrier Layer: High-density polyethylene or flexible polymer matrix

Bottom Contact Layer: Micro-textured surface to improve interface friction

Optional Cushion Layer: Nonwoven geotextile for impact protection

Manufacturing Process

Standardized engineering production workflow:

Raw Material Dosing: Virgin HDPE/LLDPE resin with antioxidant and carbon black masterbatch

Drying and Conditioning: Hopper drying to maintain moisture below technical thresholds

Flat Die Extrusion: Multi-zone heating system controlled between 180–220°C

Sheet Forming: Precision calendering for thickness control

Surface Texturing: Embossing rollers for friction optimization

Automatic Cooling: Water-cooled conveyor stabilization

Inline Monitoring: Laser thickness gauges and spark testing equipment

Final Winding: Tension-controlled automatic roll systems

Industry Comparison

| Material Type | Impermeability | Chemical Resistance | Installation Speed | Typical Service Life |

|---|---|---|---|---|

| Geomembrane for Construction Engineering | Very High | High | Fast | 25–50 Years |

| Bituminous Membrane | Medium | Low | Medium | 10–20 Years |

| Cementitious Coating | Low | Medium | Slow | 8–15 Years |

Application Scenarios

Foundation waterproofing systems for commercial and industrial buildings

Tunnel and subway structural water barriers

Basement and underground parking deck linings

Bridge abutment and retaining wall protection layers

Water reservoirs and temporary cofferdams

Core Pain Points and Engineering Solutions

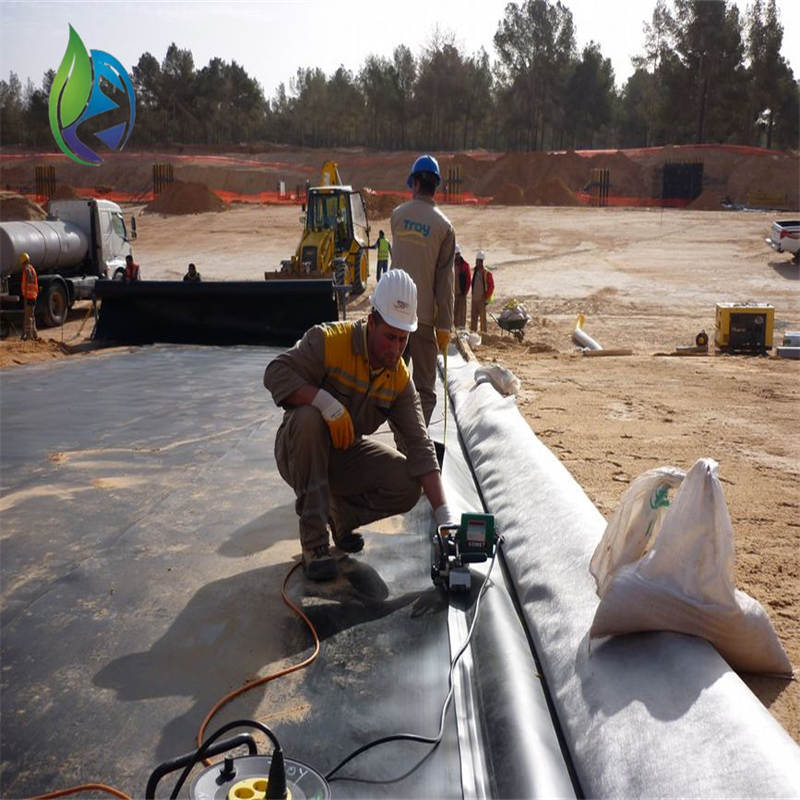

Uncontrolled Seepage: Hot-wedge welded seams with air-channel testing

Mechanical Damage from Backfill: Installation of protective geotextile layers

Chemical Attack from Soil Contaminants: Use of antioxidant-stabilized polymers

Thermal Movement Stress: Flexible anchoring and expansion design zones

Risk Warnings and Mitigation Recommendations

Risk: Poor seam quality caused by dusty surfaces

Mitigation: On-site seam surface cleaning before weldingRisk: Subgrade settlement after installation

Mitigation: Geotechnical compaction and bearing capacity verificationRisk: Long-term UV degradation

Mitigation: Early backfilling or temporary UV coversRisk: Inadequate drainage behind liner

Mitigation: Design composite drainage layers

Procurement and Selection Guide

Identify project exposure conditions (water table, chemicals, temperature)

Select thickness based on hydraulic head and structural loads

Specify texture requirements for slope stability

Define welding technology and seam testing protocols

Request factory quality management documentation

Verify third-party laboratory test reports

Plan logistics for roll sizes and lifting equipment

Engineering Application Case

In a 60,000 m² underground parking structure project, Geomembrane for Construction Engineering was installed as a continuous waterproofing barrier beneath the reinforced concrete base. The system used textured sheets and double-track welding, achieving stable long-term groundwater isolation performance under permanent hydrostatic pressure conditions.

FAQ

Q1: Suitable thickness for foundation works? A: Typically 1.0–1.5 mm.

Q2: Can it be welded in cold climates? A: Yes, with controlled preheating.

Q3: Standard overlap width? A: 100–150 mm.

Q4: Can it be used with shotcrete? A: Yes, with separation geotextile layers.

Q5: Expected service life? A: 25–50 years depending on exposure.

Q6: Resistance to hydrocarbons? A: Good resistance to typical fuel oils.

Q7: Repair method? A: Extrusion welded patches.

Q8: Fire behavior? A: Self-extinguishing grades are available.

Q9: Storage durability before installation? A: Up to 12 months under cover.

Q10: Can it be installed on vertical walls? A: Yes, with mechanical anchoring.

Call to Action

To request a formal quotation, technical datasheets, or engineered samples for Geomembrane for Construction Engineering, please submit full project specifications to the technical sales team.

E-E-A-T Author Credentials

This document is prepared by a geotechnical engineering specialist with over 15 years of experience in civil waterproofing systems, containment design, and large-scale construction engineering consultancy.