Polyethylene Geomembrane

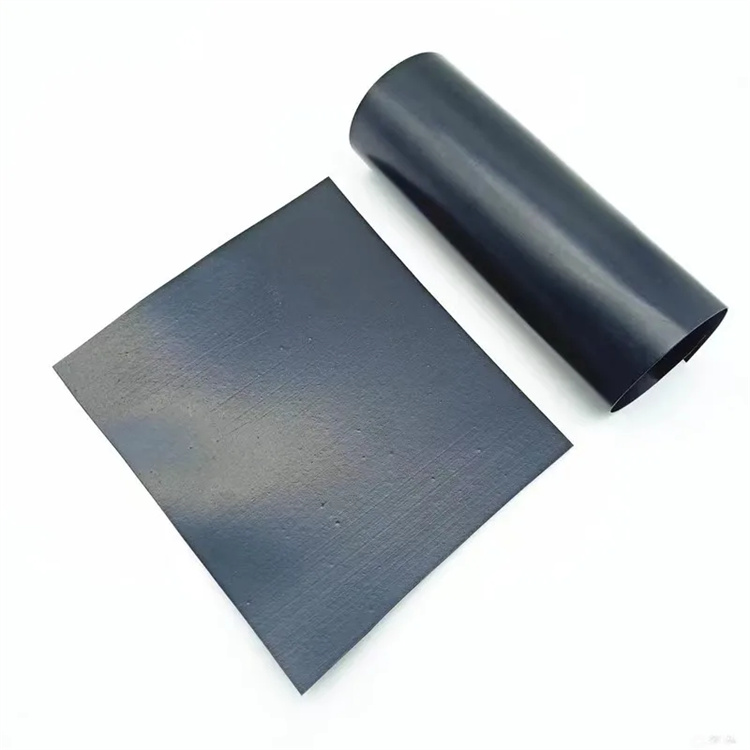

High density polyethylene film

A waterproof barrier material (density 0.94g/cm³ or above) produced from (medium) high density polyethylene resin has excellent environmental stress cracking resistance, low temperature resistance, anti-aging, corrosion resistance, and a large temperature range (-60℃- +60℃) and a long service life (up to 50 years).

Support bulk ordering with favorable prices.

Support ODM/OEM.

The factory has stock and fast delivery.

Delivery Time: 10-20 working days

Minimum Order Quantity: 300 square meters

Payment Term: 30% T/T Deposit, 70% T/T Before Shipping

Polyethylene Geomembrane: A Durable Solution for Environmental Protection

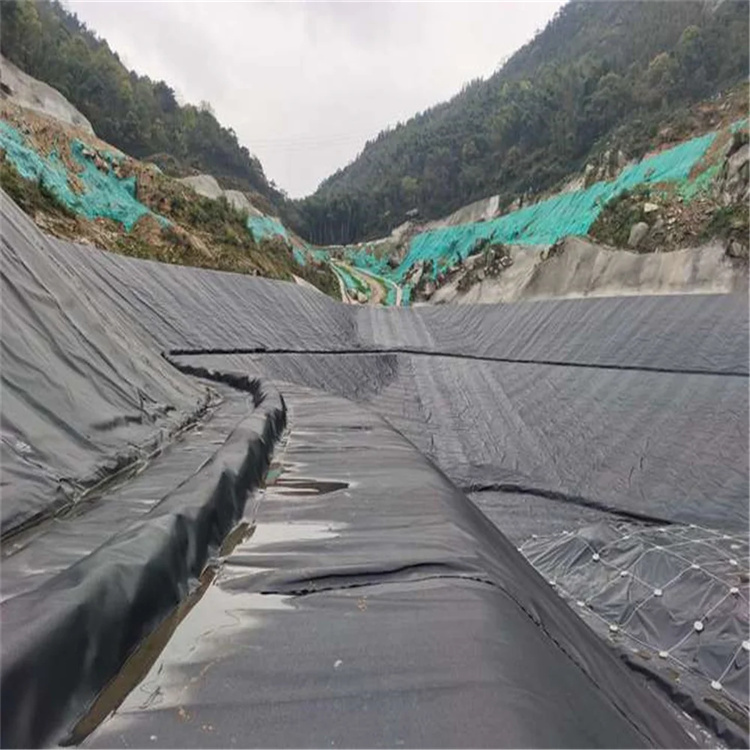

Polyethylene geomembrane is a high-performance synthetic liner used in a variety of industries for fluid and gas containment. Known for its durability and versatility, polyethylene geomembrane has become the go-to solution for many environmental protection projects. Whether in landfills, reservoirs, or agricultural applications, polyethylene geomembranes provide an effective barrier against contamination, ensuring that harmful substances do not escape into the surrounding environment.

What is Polyethylene Geomembrane?

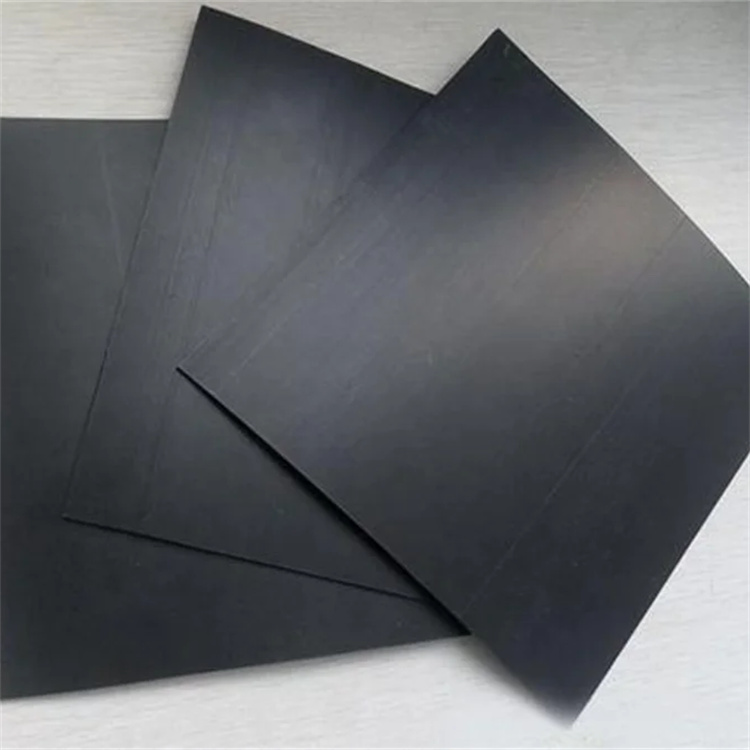

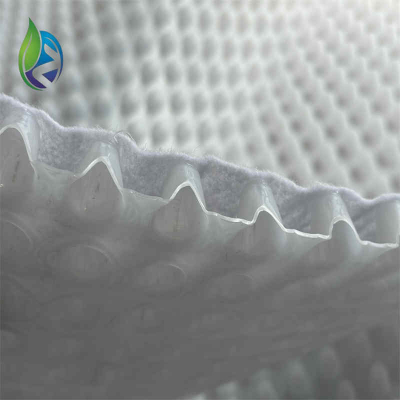

A polyethylene geomembrane is a flexible, impermeable sheet made from polyethylene resins. It is designed to serve as a barrier, preventing the migration of liquids and gases. The primary types of polyethylene geomembranes used in construction and environmental engineering are HDPE (High-Density Polyethylene) and LDPE (Low-Density Polyethylene). These materials are widely regarded for their high tensile strength, chemical resistance, and low permeability.

Applications of Polyethylene Geomembrane

Landfills and Waste Containment: One of the most common uses of polyethylene geomembrane is in landfill liners. These geomembranes prevent leachate, a toxic liquid produced by waste decomposition, from contaminating the surrounding soil and groundwater. The impermeable nature of polyethylene ensures that hazardous substances are contained.

Water Reservoirs: In water storage applications, polyethylene geomembrane serves as an effective liner for ponds, lakes, and reservoirs. It prevents water loss due to seepage, ensuring that stored water remains in the reservoir and does not contaminate the surrounding soil.

Agricultural Uses: Polyethylene geomembrane is commonly used in agricultural applications, such as greenhouse covers and pond liners. Its durability and flexibility make it an ideal material for creating controlled environments for plant growth and irrigation systems.

Mining: In mining operations, polyethylene geomembranes are used to line tailing ponds, heap leach pads, and other containment areas. These geomembranes are resistant to the chemicals and heavy metals commonly found in mining waste, preventing contamination of the surrounding land and water.

Benefits of Polyethylene Geomembrane

Durability and Longevity: Polyethylene geomembrane is resistant to UV radiation, extreme temperatures, and chemical degradation, making it an ideal material for long-term use in harsh environments.

Cost-Effective: Compared to other materials like concrete or clay liners, polyethylene geomembrane is more affordable and easier to install, which makes it a popular choice for large-scale projects that require budget-friendly solutions.

Environmental Protection: The primary benefit of polyethylene geomembrane is its ability to protect the environment from contamination. By preventing the escape of harmful substances, it helps preserve soil, groundwater, and surrounding ecosystems.

Flexibility: Polyethylene geomembranes are highly flexible and can easily conform to different shapes and surfaces. This makes them suitable for a wide range of applications, even in areas with complex topography.

Key Features of Polyethylene Geomembrane

When selecting a polyethylene geomembrane for your project, consider the following features:

Thickness: Thicker geomembranes provide added strength and durability for more demanding applications.

Chemical Resistance: The material should be resistant to the chemicals it will be exposed to, especially in industries like mining and waste containment.

Seam Strength: The seams and joints of the geomembrane must be securely welded or sealed to ensure that there are no leaks or vulnerabilities.

UV Resistance: For outdoor applications, ensure that the geomembrane has sufficient UV resistance to prevent degradation from sunlight.

Conclusion

Polyethylene geomembrane is a versatile and essential material for protecting the environment and ensuring the safety of various engineering and construction projects. Its excellent chemical resistance, durability, and impermeability make it an ideal choice for landfill liners, water reservoirs, agricultural uses, and more. By choosing the right polyethylene geomembrane for your project, you can ensure long-lasting performance and environmental protection.