Composite Drain Sheet

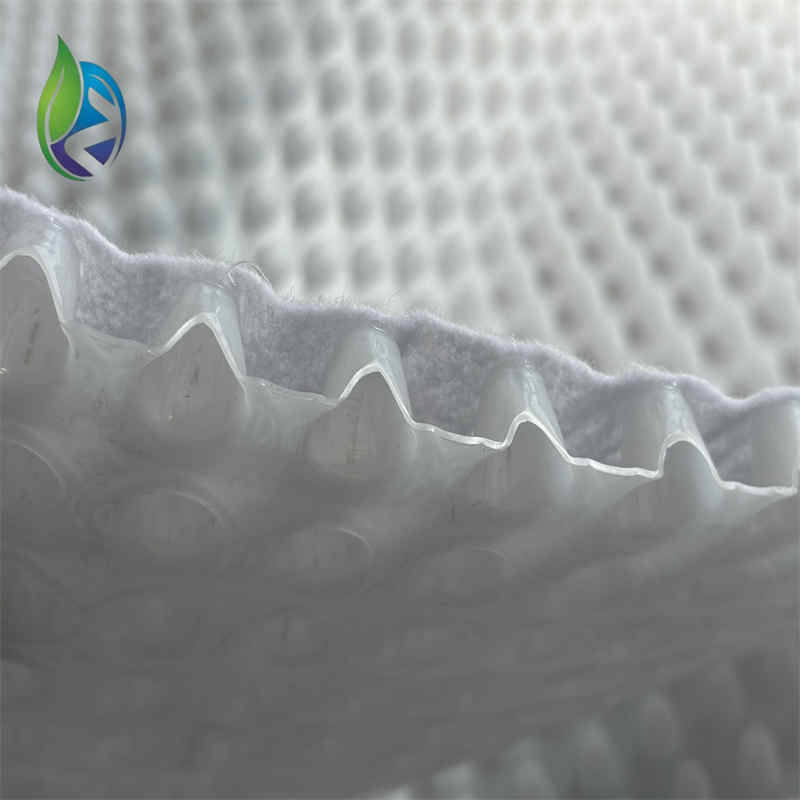

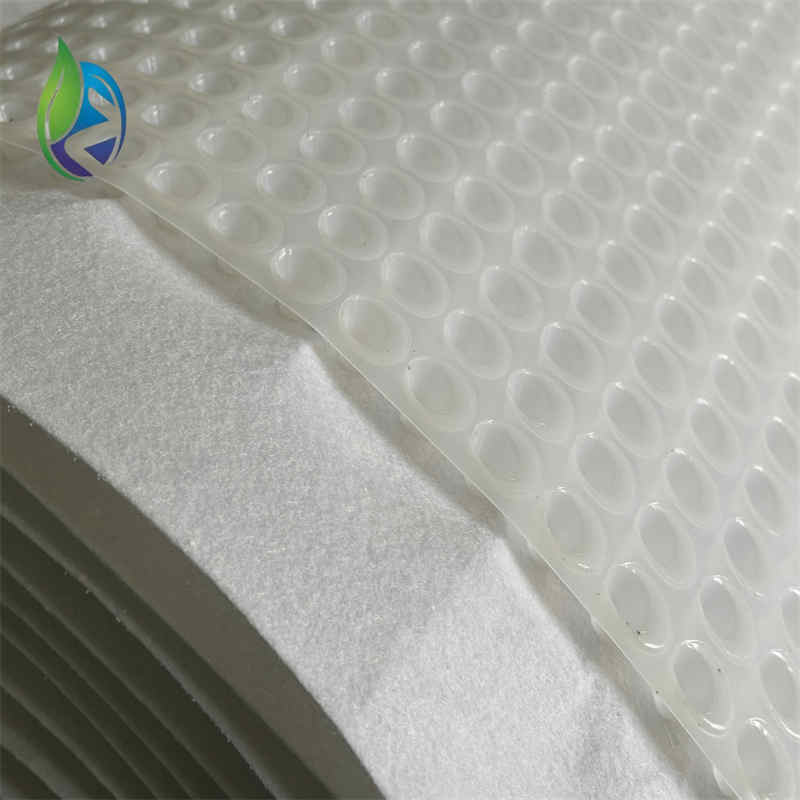

The Composite Waterproof Board with Geotextile is an innovative material that combines the durability and waterproofing capabilities of a traditional waterproofing membrane with the filtration and reinforcement properties of geotextile. This hybrid construction ensures superior performance in a range of applications, particularly in the fields of roofing, landscaping, and civil engineering.

The waterproofing board serves as the primary barrier against water infiltration, utilizing advanced polymer materials to create a seamless and impermeable surface. This layer effectively seals the underlying structure, preventing moisture damage and extending the lifespan of the installation.

The integrated geotextile, on the other hand, provides several crucial benefits. Its porous structure allows water to pass through while filtering out soil particles, preventing clogging and maintaining drainage efficiency. Additionally, the geotextile offers reinforcement, strengthening the overall structure and resisting deformation or puncturing.

Advantages of Geotextile Composite Drainage Boards

Geotextile composite drainage boards are layered functional materials combining a geotextile (permeable, filtering) with a drainage core (water-conducting, load-bearing). They are widely used in civil engineering, environmental management, and waterproofing applications. Key advantages include:

1. High-Efficiency Drainage & Anti-Clogging

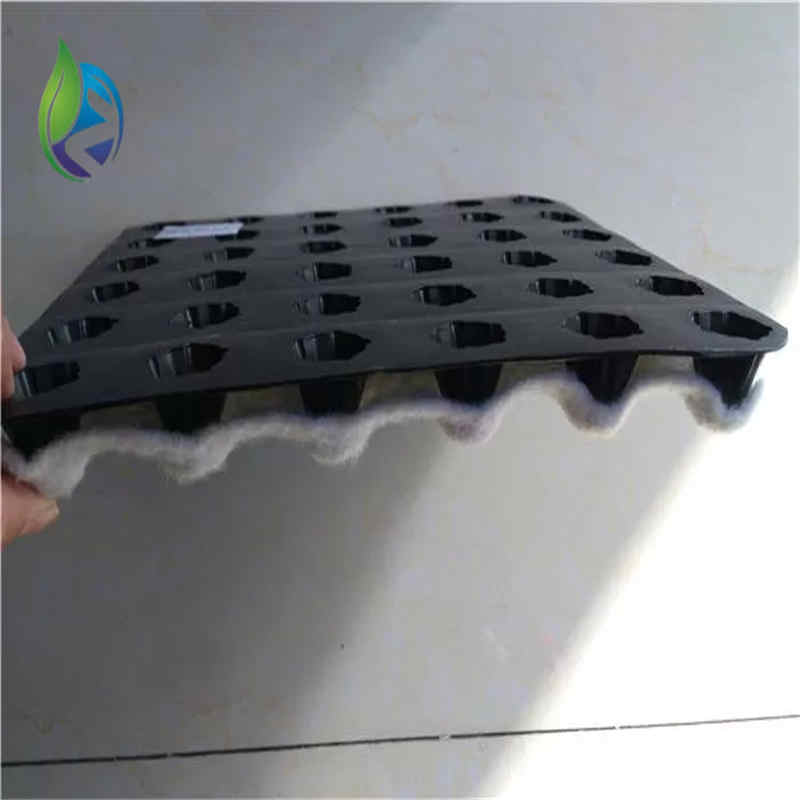

3D Drainage Structure: The corrugated or grid-patterned core provides continuous drainage channels to rapidly discharge groundwater or leachate, preventing structural damage from water accumulation.

Filtration Protection: The geotextile layer filters sediment, avoiding blockages and maintaining high hydraulic conductivity (e.g., ≥0.5 cm²/s).

2. Lightweight & Easy Installation

Weight is only 1/10 to 1/5 of traditional gravel drainage layers, reducing transportation and labor costs.

Roll-form design adapts to complex terrains; direct laying minimizes excavation and shortens construction time.

3. High Load-Bearing Capacity & Durability

The drainage core (HDPE/PP material) offers compressive strength ≥250 kPa, resisting backfill soil or vehicle loads.

The geotextile resists corrosion, UV degradation, and chemical exposure, ensuring a service life exceeding 30 years.

4. Multifunctional Integration

Drainage + Protection: Combines drainage, isolation, and impermeability (when paired with geomembranes), eliminating multi-layer construction.

Structural Safety: Mitigates groundwater pressure on foundations, preventing frost heave, landslides, and subsidence.

5. Eco-Friendly & Cost-Effective

Reduces gravel mining and ecological disruption; recyclable materials align with green engineering practices.

Total costs are 20%~40% lower than traditional drainage systems, with minimal maintenance requirements.

Technical Data:

Item Model | DB08 | DB10 | DB12 | DB16 | DB20 | DB25 | DB30 | DB40 |

Material | HDPE | |||||||

Dimle Height (mm) | 8 | 10 | 12 | 16 | 20 | 25 | 30 | 40 |

Unit weight (g/㎡) | 1000 | 1100 | 1200 | 1400 | 1500 | 1600 | 1800 | 2200 |

Thickness(mm) | 0.7 | 0.8 | 0.9 | 1.0 | 1.1 | 1.1 | 1.2 | 1.3 |

Tensile Strength(KN/m) | 3.5 | |||||||

Compressive Strength(>Kpa) | 300 | |||||||

Elongation≥% | 80 | |||||||

Longitudinal Drainage>c㎡/S | 10 | 10 | 10 | 15 | 15 | 15 | 20 | 20 |

Application Fields of Geotextile Composite Drainage Boards

Geotextile composite drainage boards, with their integrated functions of drainage, filtration, and load-bearing, are widely used in engineering scenarios requiring efficient water management and foundation protection. Key application areas include:

1. Transportation Engineering

Road/Railway Subgrades:

Prevent groundwater infiltration from softening subgrades and enhance settlement resistance.

Drain rainwater to mitigate frost heave and mud pumping (especially in cold regions).

Airport Runways/Parking Lots:

Rapidly discharge surface water to avoid积水 (waterlogging) and maintain ground stability.

2. Building Construction

Basement Roofs/Floors:

Moisture-proof drainage to prevent water seepage from damaging structures.

Tunnels/Subway Projects:

Post-lining drainage to reduce hydrostatic pressure and protect tunnel integrity.

3. Environmental & Municipal Engineering

Landfills:

Drain leachate to prevent soil and groundwater contamination (often paired with impermeable geomembranes).

Wastewater Treatment Ponds:

Base drainage layer to prevent sewage leakage.

4. Hydraulic Engineering

Reservoir/Canal Slopes:

Drain internal water from dam bodies to prevent leakage-induced landslides.

Embankment Reinforcement:

Enhance drainage and erosion resistance using geotextile integration.

5. Urban Infrastructure

Sponge City Systems:

Rapid drainage for green roofs and sunken greenbelts to alleviate urban flooding.

Rainwater harvesting and controlled release for sustainable water reuse.

Sports Fields (Soccer Pitches, Golf Courses):

Efficient drainage to maintain surface dryness and usability.

6. Agriculture & Mining

Farmland Drainage Ditches:

Prevent waterlogging and improve soil aeration.

Tailings Ponds/Mine Drainage:

Drain slag leachate to reduce heavy metal pollution risks.

Typical Application Structures

Road Subgrade Drainage System:

Structure: Graded gravel layer + Geotextile composite drainage board + Impermeable geomembrane (optional).

Function: Layered drainage, anti-clogging, and pollutant isolation.Landfill Leachate Drainage Layer:

Structure: HDPE geomembrane + Geotextile composite drainage board + Gravel protection layer.

Role: Dual impermeability + high-efficiency leachate drainage.

Core Advantages Driving Applications

Lightweight: Replaces traditional gravel layers, reducing load (ideal for green roofs and lightweight structures).

Durability: Compressive strength ≥250 kPa, suitable for heavy vehicle loads or deep burial.

Rapid Installation: Roll-based deployment cuts construction time by over 50%.

Packaging:

Customer's company Logo mark can be added.

Packed in woven bags.

Why Choose US: