Plastic Drainage Cell

Manufacturing Process

Industrial production of Plastic Drainage Cell involves standardized engineering processes:

Polymer granule drying and filtration to ensure melt stability

High-precision injection molding using automatic mold temperature control

In-mold rib and column structure forming under controlled pressure

Automated trimming and edge finishing

Online dimensional inspection using laser measurement devices

Batch compression testing and visual quality control

Palletizing and shrink-wrapping for logistic protection

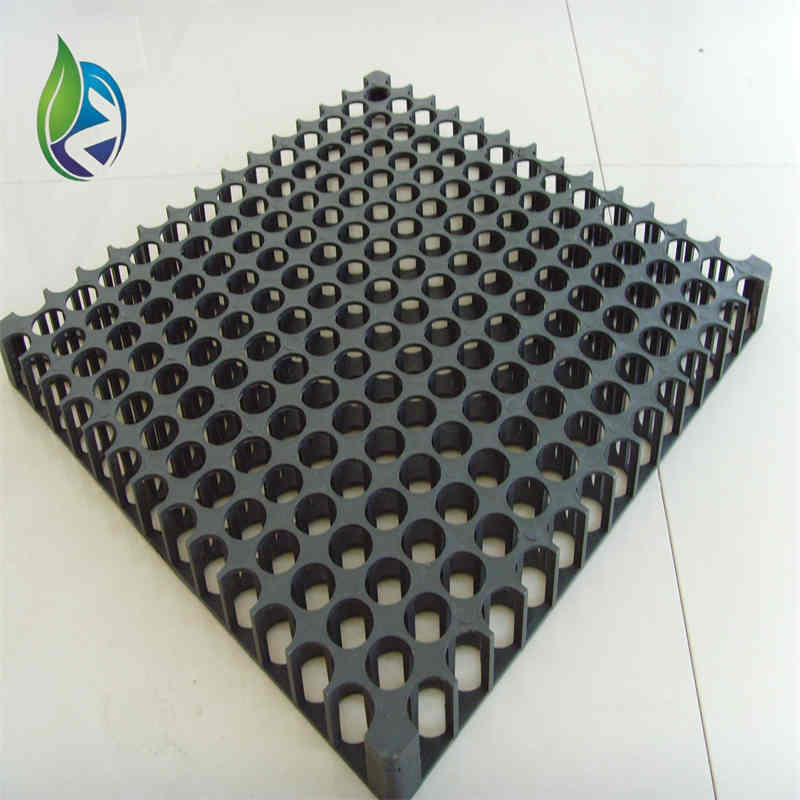

Product Definition

Plastic Drainage Cell is a modular, high-strength polymer drainage layer designed to collect, store and discharge water efficiently under structural loads. It creates a stable void structure for horizontal and vertical drainage in roofs, podium slabs, retaining walls and landscape engineering systems.

Technical Parameters and Specifications

Standard technical parameters for industrial Plastic Drainage Cell systems are listed below and commonly accepted in civil engineering applications:

Material: High-density polypropylene (PP) or recycled HDPE

Cell height: 20 mm, 25 mm, 30 mm, 40 mm, 50 mm

Compressive strength: 150–800 kPa (at 10% deformation)

Void ratio: 85%–95%

Water flow rate (horizontal): ≥ 2.5 L/s·m

Operating temperature: -30°C to +80°C

Creep resistance: ≤ 2% deformation over 50 years (design condition)

UV resistance: Stabilized for temporary exposed installation

Structure and Material Composition

Typical structural configuration of Plastic Drainage Cell:

Top plate support grid with load distribution ribs

Vertical column support nodes for compressive strength

Bottom drainage channels for controlled water collection

Material components:

Polypropylene or HDPE base polymer

Carbon black and UV stabilizers

Processing additives for impact resistance

Manufacturing Process

Industrial production of Plastic Drainage Cell involves standardized engineering processes:

Polymer granule drying and filtration to ensure melt stability

High-precision injection molding using automatic mold temperature control

In-mold rib and column structure forming under controlled pressure

Automated trimming and edge finishing

Online dimensional inspection using laser measurement devices

Batch compression testing and visual quality control

Palletizing and shrink-wrapping for logistic protection

Industry Comparison

| System Type | Drainage Capacity | Load Capacity | Installation Speed | Service Life |

|---|---|---|---|---|

| Plastic Drainage Cell | High | High | Fast | 30–50 Years |

| Gravel Drainage Layer | Medium | Medium | Slow | 10–20 Years |

| Sand Layer Drainage | Low | Low | Slow | 5–10 Years |

| Geocomposite Drain | High | Medium | Medium | 25–40 Years |

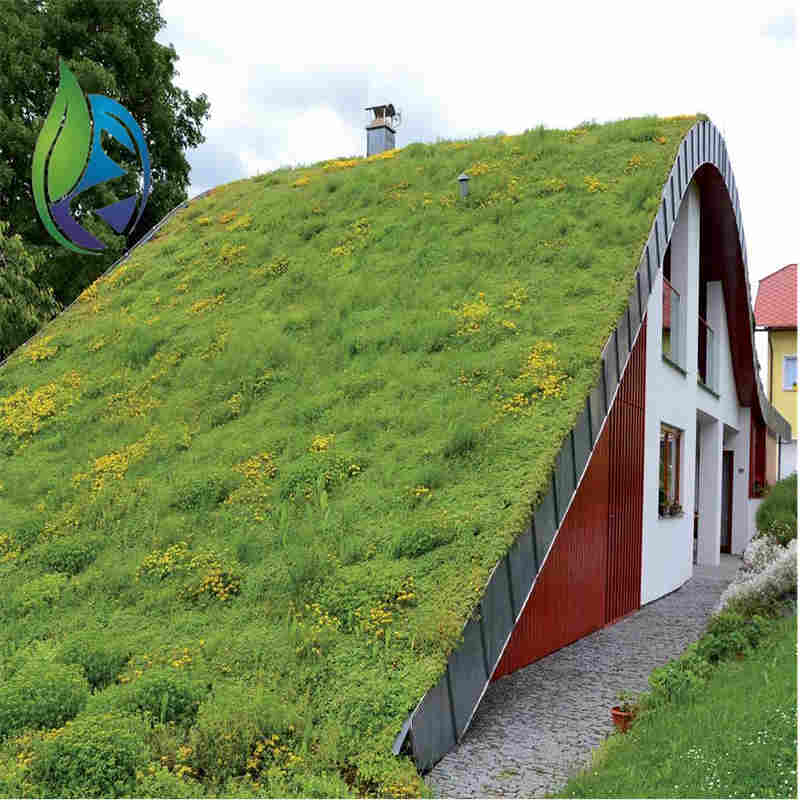

Application Scenarios

Plastic Drainage Cell is widely adopted by distributors, EPC contractors and engineering companies in:

Green roofs and rooftop gardens

Plaza decks and podium slabs

Basement and retaining wall back drainage

Sports fields and landscape projects

Infrastructure tunnel crown drainage

Key Pain Points and Solutions

Poor drainage under heavy load: High compressive strength cell structure maintains permanent flow paths.

Uneven settlement of soil layers: Modular grid provides uniform load distribution.

Clogging by fine particles: Compatible geotextile wraps prevent sediment intrusion.

Long installation time: Lightweight modular panels enable rapid on-site placement.

Risk Warnings and Mitigation Recommendations

Risk of collapse under overloading; select compressive grade according to structural design load.

Risk of UV degradation during prolonged outdoor storage; store under covers before installation.

Risk of hydraulic blockage without filtration; always combine with nonwoven geotextile.

Risk of incorrect overlap; follow manufacturer joint connection and locking procedures.

Procurement and Selection Guide

Identify project load requirements in kPa and safety factors.

Confirm required drainage height based on rainfall and runoff calculations.

Select polymer type suitable for chemical and thermal environment.

Check compliance with relevant ASTM, EN or local building standards.

Request third-party test reports for compressive strength and creep.

Verify production capacity and mold consistency of the supplier.

Evaluate packaging type for international transport efficiency.

Engineering Case Example

In a commercial podium deck project, 30 mm Plastic Drainage Cell modules with compressive strength of 500 kPa were installed over a reinforced waterproofing membrane. A nonwoven geotextile layer was placed above the cells to prevent soil intrusion. Post-installation inspections confirmed stable surface drainage and no deformation under pedestrian and landscaping loads.

FAQ

Q1: What is the most common cell height?

A: 25–30 mm.Q2: Can Plastic Drainage Cell replace gravel?

A: Yes, in most structural drainage designs.Q3: Is it suitable for traffic loads?

A: Only high-strength grades are suitable.Q4: Does it require geotextile?

A: Yes, filtration layers are recommended.Q5: What is the typical panel size?

A: Commonly 500 × 500 mm.Q6: How is flow rate tested?

A: Constant head laboratory tests.Q7: Can it be cut on site?

A: Yes, using standard hand tools.Q8: What is the service life expectancy?

A: 30–50 years.Q9: Is recycled material acceptable?

A: Only if mechanical properties meet project standards.Q10: How are panels connected?

A: Snap-lock or overlap joint systems.

CTA

For formal quotation, technical drawings or project-specific engineering samples of Plastic Drainage Cell, provide your application details to receive professional technical support.

E-E-A-T Author Credentials

This technical document is prepared by a civil engineering materials specialist with over 15 years of experience in drainage system design, geosynthetics testing and EPC project material specification.