Hdpe Smooth Geomembrane

Geomembrane, specifically designed for chemical industry projects, is a high-performance, durable, and impermeable synthetic membrane material utilized to provide effective barrier solutions against various contaminants and chemicals. It plays a crucial role in lining chemical tanks, ponds, and other storage facilities, ensuring the safe and environmentally responsible containment of hazardous substances.

Support bulk ordering with favorable prices.

Support ODM/OEM.

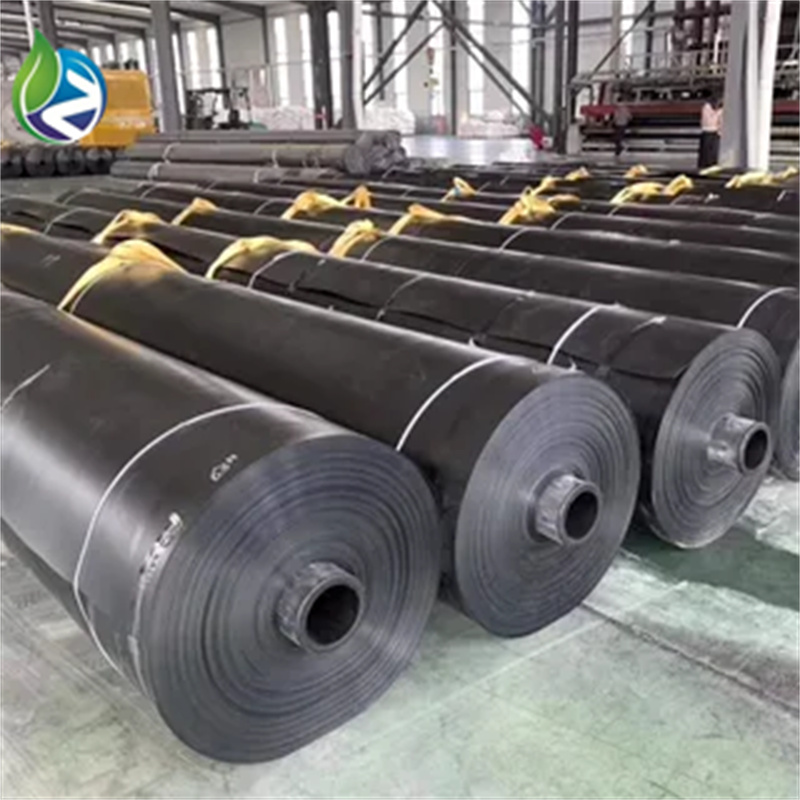

The factory has stock and fast delivery.

Delivery Time: 10-20 working days

Minimum Order Quantity: 300 square meters

Payment Term: 30% T/T Deposit, 70% T/T Before Shipping

Chemical Industry Liquid-Proof Geomembrane: Essential Protection for Industrial Safety and Efficiency

In modern industrial applications, especially within chemical manufacturing, chemical industry liquid-proof geomembrane materials have become indispensable. These advanced synthetic liners act as impermeable barriers, preventing toxic chemicals, wastewater, and corrosive substances from seeping into soil or contaminating groundwater systems. As environmental safety regulations tighten globally, the demand for chemical industry liquid-proof geomembrane solutions continues to grow.

What Is a Chemical Industry Liquid-Proof Geomembrane?

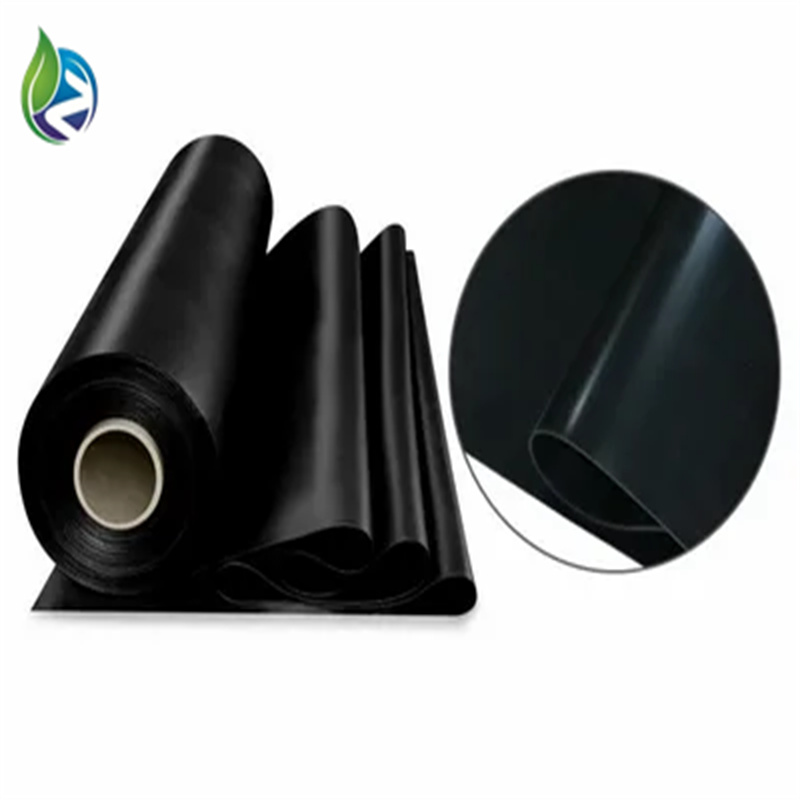

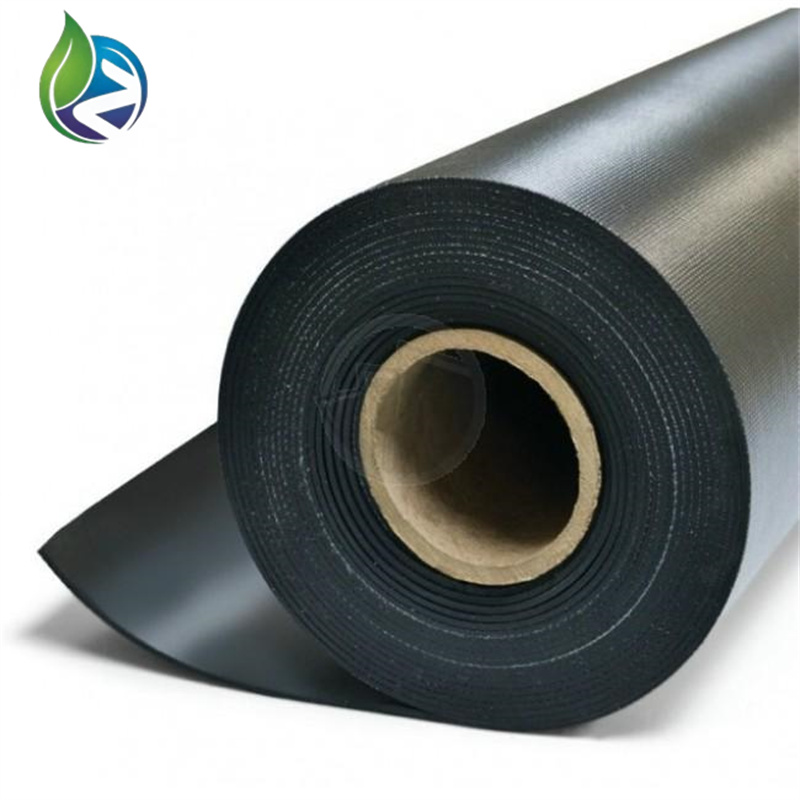

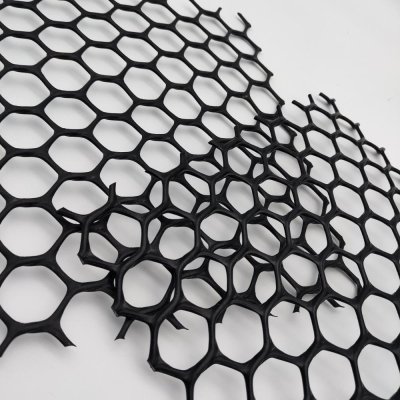

A chemical industry liquid-proof geomembrane is a highly engineered synthetic membrane used to contain hazardous liquids. Made from materials such as high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), or polyvinyl chloride (PVC), these geomembranes are chemically resistant, durable, and UV-stable. Their primary role is to line containment ponds, chemical storage areas, tanks, and landfill caps in facilities handling aggressive or toxic liquids.

Key Features of Chemical Industry Liquid-Proof Geomembrane

Superior Chemical Resistance

Designed to withstand exposure to acids, alkalis, solvents, and hydrocarbons, chemical industry liquid-proof geomembrane materials maintain integrity even in extreme chemical environments.Low Permeability

Their molecular structure ensures minimal liquid permeability, effectively isolating contaminants and preserving the surrounding ecosystem.Thermal and UV Stability

These geomembranes are built to endure fluctuating industrial temperatures and prolonged exposure to sunlight without degradation.High Tensile Strength and Flexibility

The chemical industry liquid-proof geomembrane adapts to complex installations, conforming to uneven surfaces while maintaining mechanical performance under stress.Long-Term Durability

Many products offer service lives exceeding 20 years, making them cost-effective for long-term containment projects.

Applications of Chemical Industry Liquid-Proof Geomembrane

Chemical industry liquid-proof geomembrane products are used across diverse sectors, including:

Chemical Manufacturing Plants: To line containment basins and processing areas where spillage risk is high.

Mining and Leaching Operations: To prevent leachate escape in acid heap leach pads.

Wastewater Treatment Facilities: As secure barriers in evaporation ponds and sludge holding tanks.

Pharmaceutical and Petrochemical Plants: For safe containment of volatile and reactive compounds.

Hazardous Waste Landfills: As composite liners preventing leachate infiltration.

Installation Considerations

When installing a chemical industry liquid-proof geomembrane, professionals must consider:

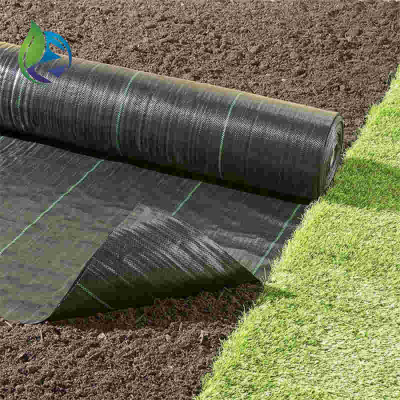

Subgrade Preparation: Ensuring smooth, compacted surfaces free of sharp objects.

Seam Welding: Thermal fusion or extrusion welding techniques must be used to create leak-proof seams.

Quality Control: On-site testing such as vacuum testing and air pressure testing verifies the membrane's integrity.

Protective Layers: In high-abrasion environments, geotextiles or sand layers are placed above the membrane.

Environmental and Economic Advantages

Utilizing a chemical industry liquid-proof geomembrane helps companies:

Comply with Regulatory Standards: Avoiding legal penalties related to environmental contamination.

Prevent Soil and Water Pollution: Protecting ecosystems and public health.

Reduce Operational Risk: Minimizing chemical loss, fire risk, and equipment corrosion.

Lower Maintenance Costs: Reliable long-term performance reduces the need for repairs or replacements.

Why Choose a Chemical Industry Liquid-Proof Geomembrane?

| Feature | Benefit |

|---|---|

| High chemical resistance | Handles aggressive industrial liquids |

| Long service life | Reduced lifecycle costs |

| Environmentally protective | Prevents leakage and soil contamination |

| Flexible and adaptable | Suitable for complex terrain |

| Engineered for industrial use | Meets international containment standards |

Final Thoughts

A chemical industry liquid-proof geomembrane is not just a barrier—it's a critical safety component in the infrastructure of modern chemical facilities. From ensuring environmental compliance to safeguarding communities and reducing cleanup costs, this technology empowers industries to operate with confidence and responsibility. Choosing the right chemical industry liquid-proof geomembrane means investing in performance, protection, and peace of mind.