Poultry Farm Custom Biaxial Plastic Geogrid

Structure and Material Composition

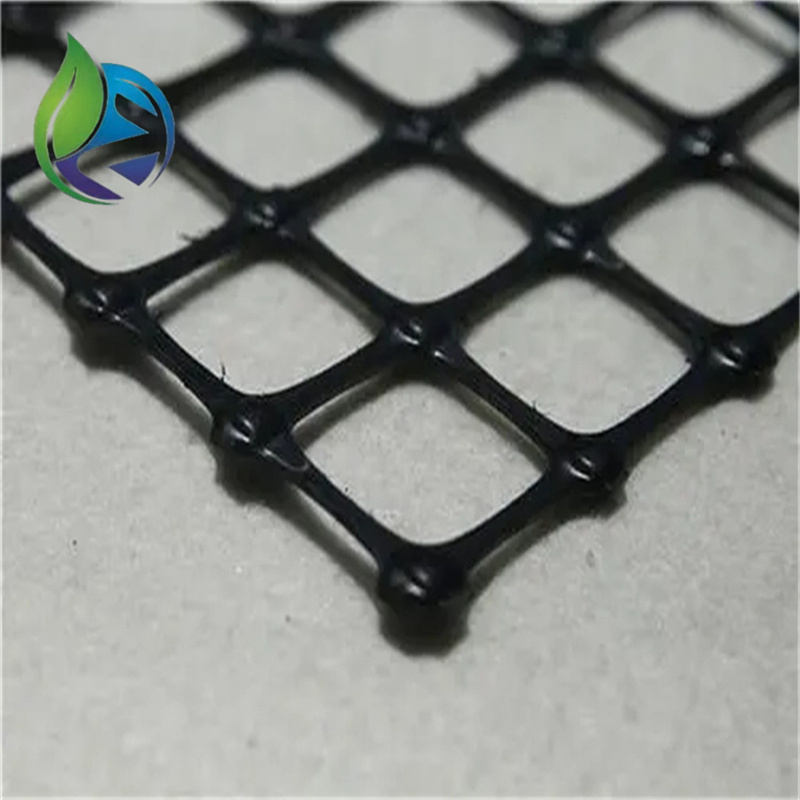

The geogrid adopts a rigid grid structure optimized for load transfer and interlocking with granular fill:

Base Polymer Layer: High-molecular PP or HDPE providing chemical resistance and durability

Biaxial Node Structure: Uniformly stretched junctions ensuring balanced strength in both directions

Aperture Geometry: Designed to interlock with crushed stone or gravel bedding

Surface Texture: Enhanced friction to improve soil-geogrid interaction

Product Definition: Poultry Farm Custom Biaxial Plastic Geogrid

Poultry Farm Custom Biaxial Plastic Geogrid is a polymer-based soil reinforcement material engineered for poultry house foundations, access roads, and service yards. It provides bidirectional tensile strength to improve load distribution, reduce settlement, and enhance long-term ground stability under livestock facility conditions.

Technical Parameters and Specifications

The following parameters are commonly adopted for poultry farm engineering projects and can be customized based on load and soil conditions:

| Parameter | Typical Specification |

|---|---|

| Polymer Type | PP or HDPE |

| Structure | Biaxial stretched grid |

| Tensile Strength (MD/TD) | 20–50 kN/m |

| Elongation at Break | ≤12% |

| Aperture Size | 30×30 mm to 60×60 mm |

| Roll Width | 3.0–6.0 m |

| Roll Length | 50–100 m |

| Design Life | ≥20 years (buried condition) |

Structure and Material Composition

The geogrid adopts a rigid grid structure optimized for load transfer and interlocking with granular fill:

Base Polymer Layer: High-molecular PP or HDPE providing chemical resistance and durability

Biaxial Node Structure: Uniformly stretched junctions ensuring balanced strength in both directions

Aperture Geometry: Designed to interlock with crushed stone or gravel bedding

Surface Texture: Enhanced friction to improve soil-geogrid interaction

Manufacturing Process and Engineering Control

Process Flow

Polymer resin selection and batching

Sheet extrusion through flat die

Precision punching of aperture pattern

Biaxial stretching under controlled temperature

Cooling and dimensional stabilization

Online tensile strength inspection

Cutting, rolling, and labeling

Key Equipment

High-capacity plastic extruder

Numerical control punching system

Biaxial stretching frame

Automatic tensile testing units

Industry Comparison

| Material | Biaxial Plastic Geogrid | Woven Geotextile | Steel Mesh |

|---|---|---|---|

| Tensile Direction | Biaxial | Uniaxial | Biaxial |

| Corrosion Resistance | Excellent | Excellent | Poor |

| Installation Speed | Fast | Medium | Slow |

| Soil Interlock | High | Low | Medium |

| Cost Efficiency | High | Medium | Low |

Application Scenarios in Poultry Farm Projects

This custom biaxial plastic geogrid is widely applied in poultry-related infrastructure:

Poultry house foundation reinforcement

Service roads for feed and waste transport

Manure handling and storage yard bases

Drainage channel side slope stabilization

Heavy equipment parking areas

Core Pain Points and Engineering Solutions

Soft subgrade settlement: Geogrid improves bearing capacity and reduces differential settlement

Repeated vehicle loading: Biaxial strength distributes loads evenly

High moisture environment: Polymer material resists water and chemical exposure

Frequent maintenance costs: Reinforced base extends service life of gravel layers

Risk Warnings and Mitigation Measures

Ensure proper overlap (≥300 mm) between adjacent rolls

Avoid direct UV exposure during long-term storage

Use well-graded aggregate for optimal interlock

Confirm tensile strength meets actual axle load requirements

Procurement and Selection Guide

Conduct soil bearing capacity assessment

Define load conditions and traffic frequency

Select suitable tensile strength grade

Determine aperture size based on aggregate type

Confirm roll dimensions for site efficiency

Request third-party test reports

Evaluate supplier customization and delivery capability

Engineering Case Application

In a large-scale poultry farm expansion project covering 18,000 m², a custom biaxial plastic geogrid with 40 kN/m tensile strength was installed beneath a 200 mm crushed stone layer. Post-construction monitoring showed a reduction in rutting by over 45% compared to untreated sections, with stable performance after 24 months of operation.

FAQ — Technical and Procurement Questions

Can the geogrid be customized for different poultry houses? Yes, tensile strength and aperture size can be adjusted.

Is it suitable for wet or muddy sites? Yes, it performs well under high moisture conditions.

What is the expected service life? Over 20 years when properly buried.

Does it require anchoring? Typically no, when covered with aggregate.

Can it be used with recycled aggregates? Yes, if gradation meets design requirements.

Is it resistant to manure chemicals? Yes, PP and HDPE offer strong chemical resistance.

How is quality verified? Through tensile, junction strength, and dimensional tests.

What roll sizes are available? Standard and custom widths and lengths.

Is installation equipment required? No specialized equipment is needed.

Does it meet international standards? Typically compliant with ASTM and ISO standards.

Request Quotation or Technical Documentation

For customized specifications, engineering drawings, laboratory test reports, or project-based quotations, procurement and engineering teams are encouraged to request formal technical documentation and material samples for evaluation.

E-E-A-T: Authoritative Technical Background

This article is prepared by geosynthetics engineering specialists with extensive experience in agricultural infrastructure, soil reinforcement design, and international project supply, supporting EPC contractors, distributors, and farm developers worldwide.