What is a Biaxial Stretch Plastic Geogrid

If you're diving into civil engineering or geotechnical projects, you've likely heard of biaxial stretch plastic geogrids—but what exactly are they, and why are they such a game-changer in soil reinforcement?

In this in-depth guide, we’ll explain what a biaxial stretch plastic geogrid is, how it works, where it’s used, and why it's trusted across construction sites worldwide. Whether you're a contractor, project manager, or supplier, understanding the full potential of this material can help you build better and safer.

? What Is a Biaxial Stretch Plastic Geogrid?

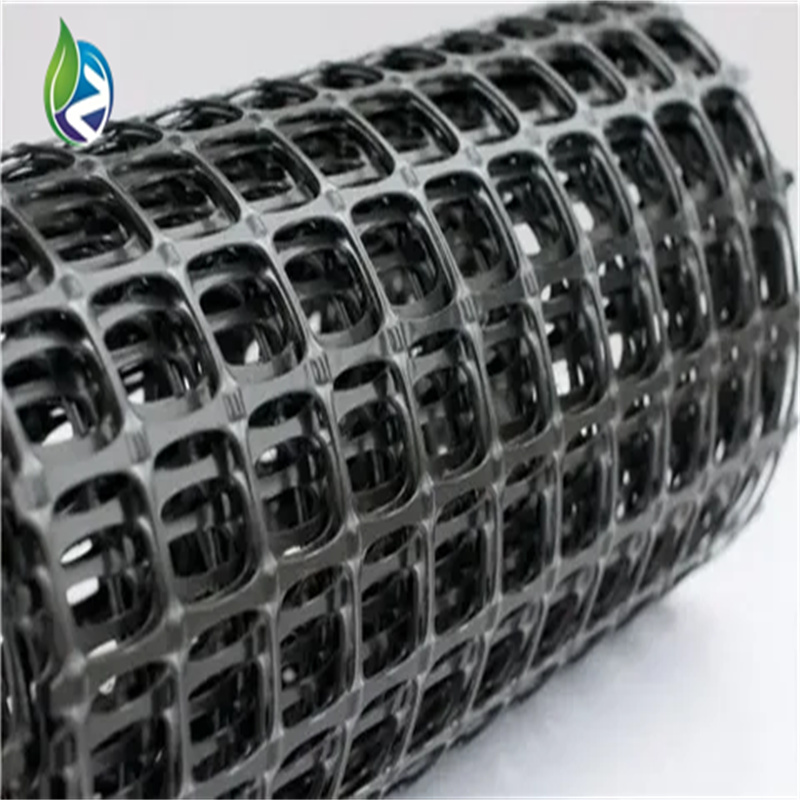

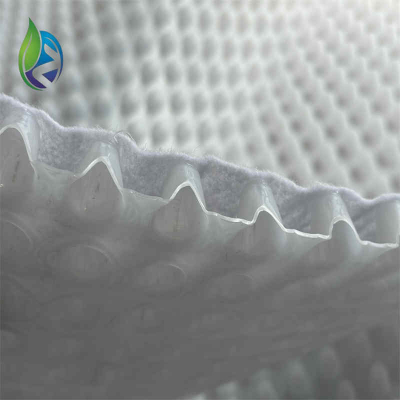

A biaxial stretch plastic geogrid is a synthetic geosynthetic material made by stretching polymer sheets (usually polypropylene or polyethylene) in both the longitudinal and transverse directions. This process forms a rigid grid structure with uniformly distributed square or rectangular apertures, giving it high tensile strength in both directions.

The core purpose of a biaxial stretch plastic geogrid is to reinforce and stabilize weak soils, reduce rutting, and distribute loads more evenly, making it a top choice for roads, railways, retaining walls, and embankments.

? "Before using biaxial stretch plastic geogrids, we had constant rutting issues on our gravel roads. Now, they last through every rainy season." — @SiteSupervisorJohn

⚙️ How Does a Biaxial Stretch Plastic Geogrid Work?

The secret lies in interlocking and load distribution.

When placed beneath layers of soil or aggregate, the biaxial stretch plastic geogrid creates a mechanical interlock with the fill material. This prevents lateral movement of the aggregate and spreads vertical loads over a wider area.

Think of it as a soil reinforcement skeleton, creating a strong, flexible foundation that improves both bearing capacity and durability.

? Key Features of Biaxial Stretch Plastic Geogrids

Here are the features that make them ideal for soil reinforcement:

High tensile strength in both directions

UV resistant, chemical resistant, and corrosion-proof

Lightweight yet structurally rigid

Easy to cut, handle, and install

Environmentally friendly, recyclable materials

? "Super easy to transport and install. We laid over 10,000 square meters in just two days with a small team." — @CivilBuildPro

?️ Applications of Biaxial Stretch Plastic Geogrids

Biaxial geogrids are widely used in:

Road and highway base reinforcement

Railway track bed stabilization

Airport runways and taxiways

Retaining wall backfill stabilization

Parking lots, industrial yards, and container terminals

Landfills and embankments for erosion control

Their versatility makes them a go-to for both temporary and permanent infrastructure projects.

? Installation Process: Quick Overview

Site Prep: Level and compact the subgrade.

Unroll the Geogrid: Lay it flat over the prepared surface.

Overlap: Ensure 20–30 cm overlap at joints.

Anchor and Secure: Use pins or staples to hold in place.

Backfill: Place aggregate or soil over the geogrid and compact.

? "Even our junior crew got the hang of it quickly. It's a smart solution that doesn’t need complex tools or training." — @GravelTechManager

? Performance Benefits

Reduces aggregate thickness by up to 40%

Improves pavement life by 2–3 times

Decreases construction time and long-term maintenance costs

Enhances drainage and erosion control

These benefits make it a cost-effective and eco-friendly solution.

? FAQs About Biaxial Stretch Plastic Geogrid

✅ Is it better than uniaxial geogrid?

Yes, for load-spreading applications like roads and flat foundations, biaxial geogrids are ideal because they provide strength in two directions, unlike uniaxial which is directional.

✅ Can it be used in wet or coastal areas?

Absolutely. Biaxial stretch plastic geogrids are chemically inert and resistant to water, salt, and acids, making them suitable for marine or wetland foundations.

✅ Is it recyclable?

Yes. Most plastic geogrids are made from polypropylene (PP) or high-density polyethylene (HDPE) and are 100% recyclable.

? Real Users. Real Impact.

⭐⭐⭐⭐⭐

“We used biaxial stretch plastic geogrid for our warehouse floor foundation. Not a single crack after 3 years of heavy truck traffic.”

— @LogisticsSiteEngineer

⭐⭐⭐⭐⭐

“I recommend this to every contractor I know. Especially for sub-base stabilization—it’s unbeatable.”

— @EarthworksGlobal

? Final Thoughts: Why Choose Biaxial Stretch Plastic Geogrids?

Understanding what a biaxial stretch plastic geogrid is helps you make smarter decisions for your next project. Its strength, ease of use, and long-term performance make it one of the most cost-effective geotechnical materials on the market.

If you're aiming to improve load distribution, reduce costs, and future-proof your infrastructure—biaxial stretch plastic geogrids are a must.

? Need a reliable supplier or technical consultation? Contact us today for free support and bulk pricing!