New geocells empower ecological restoration

New Geocells Empower Ecological Restoration

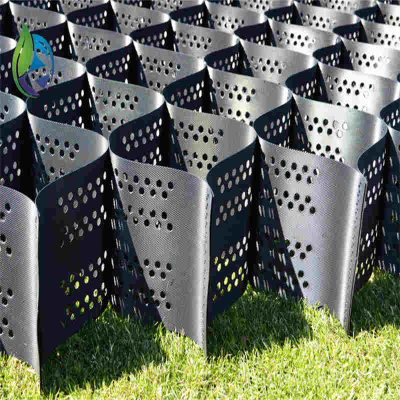

These days, more and more people around the world are focusing on ecological protection. You know the usual problems—soil washing away, slopes that feel wobbly, plants that just won’t grow. All of this is getting worse. Cities keep spreading, we’re building more roads and buildings, and extreme weather hits more often. All this messes up natural ecosystems, and we really need good, sustainable ways to fix it. That’s where new-type geocells come in—they’re changing the game. Practical tools, you see, that balance engineering work with protecting the environment. These 3D cellular things are made to stabilize soil and help plants grow, and they’re shifting how we do ecological restoration projects everywhere. What makes them stand out? Not just their flexibility, but geocell specifications matter a lot too. They’re set up to fit different environmental conditions and what you actually need from a restoration project.

The Core Role of New Geocells in Ecological Restoration

Ecological restoration isn’t simple. You have to tackle a bunch of problems at once—stop soil from washing away, and get native plants growing again. Old methods, like concrete slope protection or even digging soil by hand? They usually don’t work great. Too stiff, bad for the environment, and they don’t last long either. New geocells are different. They work with nature, not against it. Use their unique structure to make stable spots where plants can actually take root and grow.

One big use for these geocells is slope stabilization. Super key for restoration projects—whether you’re working on highways, mines, or riverbanks. Slopes erode easy, or slide, especially after construction or a storm. Fixing their stability? Total must if you want to protect the ecosystems nearby. Here’s how it works: you lay the new geocells on the slope, then fill ’em with soil, gravel, or a mix of stuff that helps plants grow. This makes a matrix that’s strong but flexible, too. Locks soil particles in place, so water doesn’t run off and cause erosion. Geocell specifications play a big role here. Things like how tall the cells are, how thick their walls are, how durable the material is—all of this gets adjusted to handle the slope’s steepness, what kind of soil you’re dealing with, and the local weather. Like, steeper slopes need geocells that are taller and have more tensile strength to stay intact. Areas with heavy rain? They need cells that drain well—so water doesn’t pool up and cause trouble.

Geocells are also great for fixing bad soil and bringing plants back. A lot of damaged areas have soil that’s no good—too compact, not enough nutrients, or no organic matter at all. Plants can’t take root there easy. Geocells fix that by making a structured space for growing. The cells hold onto moisture and nutrients, so they don’t wash away. Helps seeds sprout, roots grow. Pair geocells with native plants, and vegetation comes back fast. That makes the soil even more stable, and gives wildlife a place to live too. Geocell specifications like cell size and aperture matter here, too. They decide how well roots can push through the soil, and how well water and nutrients stay put. Bigger cells work for plants with deep roots, while smaller ones are better for grasses or low-growing stuff.

Key Elements of Geocell Specifications

If you want to get why new geocells work so well for ecological restoration, you need to break down the key geocell specifications that shape how they perform. These specs aren’t one-size-fits-all—they get tweaked to fit what each project actually needs. That’s why they work well in different places.

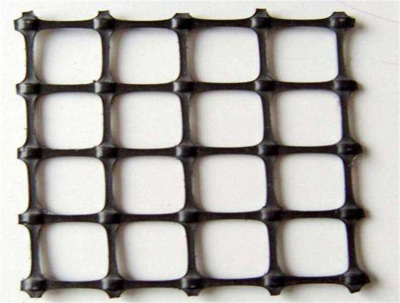

First off, picking the right material is a basic geocell specification. Most modern geocells are made from HDPE (high-density polyethylene) or PP (polypropylene). Both are durable, resist UV rays, and don’t react to chemicals. HDPE’s the go-to if you need something that’ll last through harsh winters or scorching summers—doesn’t break down easy. PP’s more flexible, so it’s perfect for slopes with bumpy surfaces or areas that move a little, like spots where the ground shifts after rain. The material you pick affects how long the geocell lasts, and how well it works. That’s a big deal for ecological restoration—these projects aren’t just for a few months, you know? They’re supposed to help the environment for years.

Then there’s cell dimensions—those matter a lot for geocell specs. This includes how tall, long, and wide the cells are, plus the size of the apertures (the holes in the walls). Cell height usually goes from 50mm to 300mm. Taller cells hold more soil and stay more stable—good for steeper slopes or heavier loads, like if you’re covering a slope with thick topsoil. Cell length and width change based on how big the project is. Standard rolls are easy to install, and you can cut ’em to fit without wasting much. Aperture size is just the size of the holes in the geocell walls. It affects how water drains, how roots grow through, and how air gets into the soil. For ecological restoration, we usually pick aperture sizes that let plant roots go through the walls but keep soil particles in place. It’s a balance—keep things stable, but let plants grow too.

Tensile strength and modulus are important geocell specifications too. Tensile strength is how well the geocell resists stretching or tearing when something’s pushing on it—like if a heavy rain soaks the soil and adds weight. Modulus is how stiff it is. These two things keep the geocell’s structure intact when soil, plants, wind, or water put pressure on it. Steeper slopes or heavy soil? You need geocells with higher tensile strength—otherwise, they’ll warp over time, and the soil might slide. Modulus makes sure the geocell’s stiff enough to hold the soil, but flexible enough to handle small ground movements. Useful in places where the ground might settle a little, like old construction sites or former mine areas.

Environmental Advantages of New Geocells

New geocells don’t just work well—they’re good for the environment too. That lines up with what ecological restoration’s all about. Old methods use concrete or other stuff that never breaks down. Geocells? They’re made from recyclable plastics. Cuts down their carbon footprint. And they’re lightweight—so you don’t need heavy machinery to move ’em or install ’em. That means less fuel use, fewer emissions, which is better for the air.

Their environmental friendliness gets better because they help nature regrow on its own. Stabilize the soil, make good growing conditions, and geocells speed up how fast native plants come back. More plants mean better air quality, less erosion, and homes for wildlife—like small birds or insects that need cover. This way of restoring isn’t just “fixing” ecosystems—they start working like they naturally do again. Geocell specifications matter here, too—most materials get treated to resist UV rays, so they don’t break down fast. Stay effective for decades, and don’t let out harmful chemicals into the soil or water.

Another environmental benefit? Less construction waste. Old slope protection methods make a ton of waste—broken concrete, excess soil, stuff that ends up in landfills or pollutes nearby streams. Geocells are easy to install—you don’t have to cut ’em or modify ’em much, so there’s less waste. They’re durable too, so you don’t have to replace ’em often. Cuts down the environmental impact over the project’s whole life, which is what sustainability’s all about.

Customization of Geocell Specifications for Different Restoration Scenarios

Ecological restoration projects are all different. You might be fixing up an old mine, stabilizing a riverbank, repairing a highway slope, or bringing back a wetland. Each one has its own problems. New geocells adapt with customized geocell specifications. That flexibility’s one of their biggest strengths—work in almost any environment.

Take mine reclamation, for example. Those areas usually have really bad soil—low fertility, high acidity, sometimes even leftover chemicals. For these projects, geocell specifications get adjusted to focus on holding soil and managing nutrients. Installers might use geocells with thicker walls and more tensile strength to handle the unstable soil—since mine soil can shift a lot. Maybe bigger cells too, to hold nutrient-rich growing mix, like compost or topsoil. Aperture size might get tweaked so roots can grow deep—helps plants survive in that poor soil, since deep roots can reach more nutrients.

Riverbank restoration needs geocells that can handle being in water all the time and resist erosion from currents. Here, geocell specifications focus on water resistance and durability. HDPE geocells are often used—they don’t get ruined by water, even if they’re submerged for weeks. Cell height and weight get increased so floods don’t wash the geocells away—you don’t want all that hard work to float downstream. Aperture sizes might be smaller to hold fine soil particles—stops sediment from getting into the river, which is bad for fish, but still lets water flow through so the bank doesn’t get waterlogged.

Highway slope restoration has its own unique problems. Space is tight—you can’t block traffic to install big materials. Traffic’s heavy, so the slope can’t shift once it’s fixed. And you need to get the work done fast, so you don’t disrupt commuters. Geocell specifications here focus on easy installation and compact design. Lightweight PP geocells are common—roll ’em out quick, secure ’em with stakes, no need for big cranes or trucks. Cell dimensions get tailored to the slope’s steepness: shorter cells for gentle slopes, taller ones for steeper parts. Tensile strength matters here too—geocell’s gotta hold up under the weight of soil and plants, and not move when big trucks rumble by.

Future Trends in Geocell Technology for Ecological Restoration

Demand for sustainable ecological restoration solutions is growing. So geocell technology’s evolving too—geocell specifications and designs get better all the time. One new trend is bio-based geocells. Made from renewable stuff like corn starch or sugarcane fiber. Work just as well as traditional plastic geocells, but they’re fully biodegradable. Cuts down long-term environmental impact—you don’t have plastic sitting in the soil for 50 years. Geocell specifications for these bio-based ones are being refined to match plastic’s strength and durability. Researchers are focusing on making ’em more resistant to moisture and decomposition—so they last long enough to hold the soil while plants grow, then break down naturally without leaving junk behind.

Another trend is adding smart tech to geocells. Future geocells might have tiny sensors that track soil moisture, temperature, and nutrient levels. These sensors send real-time data to project managers—you can check your phone and see if the slope’s too dry, or if nutrients are low. Use that data to adjust maintenance plans—water more if it’s dry, add fertilizer if needed. Helps plants grow better, and makes sure restoration projects work well for the long haul. Geocell specifications for these smart geocells will include compatibility with sensor tech—they’ll have small slots to hold the sensors, and the material will protect them from dirt and water. They’ll be more durable too, so the sensors don’t get crushed by soil or roots.

Optimizing geocell specifications for extreme environments is another key area of work. Climate change is causing more extreme weather—heavy rain that floods slopes, droughts that dry out soil, heatwaves that bake materials. Geocells need to adapt to that. Hot, sunny areas? Geocells might get made with better UV resistance—so they don’t crack in the sun. Dry areas? Better water retention—maybe the material holds onto moisture a little, so plants don’t wilt. Researchers are also looking at ways to improve geocell specifications so they can handle floods and storm surges—like making them heavier or adding anchors. That makes ’em more useful for coastal restoration, where hurricanes can hit hard, or river projects that get hit by flash floods.

Conclusion

New-type geocells are powerful tools for ecological restoration. They offer a sustainable, effective way to solve some of our biggest environmental problems. Their success comes from their unique structure, environmental benefits, and most importantly—well-tweaked geocell specifications. These specs make sure they work well in different scenarios, whether you’re fixing a mine, a riverbank, or a highway slope. Whether you’re stabilizing slopes, fixing soil, or bringing back plants, geocells work with nature to restore ecosystems and keep the environment healthy long-term.

As technology advances, we’ll see even more innovative geocell designs and specifications. Tailored to meet the changing needs of ecological restoration—like handling extreme weather or using renewable materials. Bio-based materials, smart sensors, better performance in harsh spots—geocells will keep playing a key role in balancing human development with environmental protection. For project managers, engineers, environmentalists—understanding and picking the right geocell specifications is the key to getting the most out of this tech. That’s how you make sure ecological restoration projects actually work, not just look good for a year.

In a world where our planet’s health matters more than ever, new geocells are a practical, forward-thinking solution. Let’s actually fix damaged ecosystems, not just patch them up. Build a more sustainable future where we work with nature, not against it. With their flexibility, durability, and environmental benefits, they’ll end up being a go-to option in restoration projects around the world. Prove that engineering and nature can work together to make real, positive change—no fancy tricks, just smart tools and good planning.