High-strength grids lay a solid foundation for projects

High-Strength Geogrid: Fortifying the Foundation of Engineering Projects

These days, the construction industry barely slows down—seriously, not even a minute of downtime. And right along with that, the need for tough, reliable materials that boost structural stability just keeps climbing. Let’s be real: major highways, railways, residential builds, even environmental restoration work—none of these can cut corners on stable ground. It’s not a “nice extra”; it’s a total must. Engineers and contractors are always out here hunting for solutions that hit three key points: meet strict safety standards, speed up projects, and cut long-term maintenance costs. Of all construction materials, high-strength geogrid stands out as a practical fix. It gives top-tier reinforcement to solve some of modern engineering’s biggest headaches. This article breaks down how it’s changing infrastructure worldwide, focusing on its role in building stable, long-lasting structures—including the versatile geogrid retaining wall.

The Growing Need for Reliable Reinforcement

Infrastructure keeps economies moving, but it often runs into snags with soil and structural stability. A lot of job sites I’ve been to have soft, unstable soil—stuff that just can’t handle heavy loads. Over time, that leads to sinking, cracking, even total failure. Traditional go-tos? Concrete, steel—whatever’s usual. They’re pricey, soak up tons of labor, and honestly, hard on the environment. Plus, they don’t flex enough to adapt to different soils or project needs. Total pain.

But here’s the thing with cities growing and roads spreading: the pressure to build faster, safer, and greener gets stronger. That’s where geogrid comes in. Unlike rigid materials, it’s lightweight, easy to install, and works with soil—not against it. It spreads loads evenly, strengthens weak dirt, and stops erosion. And it does all this without extra digging or hauling heavy gear. One of the most useful ways to use it? The geogrid retaining wall. It gives solid support to slopes, roads, and structures where soil stability’s a real issue, y’see.

Engineers have known this for years—it’s common sense. A durable structure needs a solid foundation. Geogrid helps soil hold weight better by making a composite mix: grid strength plus the soil’s natural traits. This doesn’t just make projects more stable; it makes them last longer. So you spend less on repairs later. Whether it’s road work, landfills, or coastal protection, geogrid’s flexible and reliable. It fits the construction industry’s ever-changing needs.

Core Traits of High-Strength Geogrid

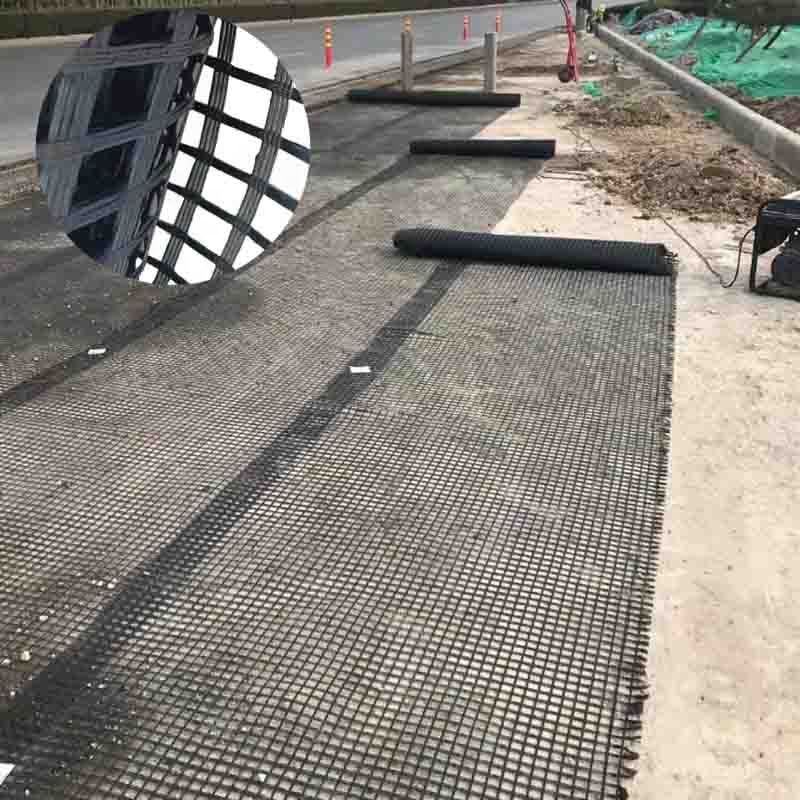

Geogrid’s different from other reinforcement options—it has unique traits that make it perfect for engineering work. At its core, it’s a synthetic material made from polymers: polypropylene or polyethylene, y’know? The kind that lasts and doesn’t break down from the elements. It’s extruded into a grid with open holes, so soil, gravel, or fill locks right in. Makes a strong, stable composite—simple as that.

Tension handling is one of its best features. Unlike traditional materials that crack when pulled, geogrid takes high stress without warping. That’s perfect for slopes or soft ground that shifts a lot. It also resists UV rays, chemicals, and mold rot. So it holds strength for decades, easy. Even in a geogrid retaining wall, these traits keep the structure steady. Extreme heat, heavy rain—doesn’t matter. It works every time.

Flexibility is another big plus. Unlike stiff concrete or steel, geogrid bends to match the land’s shape. That’s great for complex sites—like rocky terrain or odd property lines. You can cut it to size on the job, which cuts waste and simplifies work. Being lightweight means you don’t need big machinery to move it. Saves labor costs and helps the environment. Whether it’s a big highway project or a small home build, geogrid’s a practical, affordable fix.

And don’t forget it’s eco-friendly. Most geogrid uses recycled materials. Its light weight cuts carbon from transport and installation. Unlike concrete, which needs tons of energy to make, geogrid manufacturing is low-impact. Plus, using it means less soil to haul away—fewer dump trucks on the road. All this makes it a go-to for folks who want to hit sustainability goals without losing performance.

Road Construction: Stability for Busy Routes

Road work’s one of the most common—and critical—uses for geogrid, honestly. Highways, local roads, rural routes—they all take constant strain from traffic, weather, and soil movement. Without good reinforcement, roads get potholes, cracks, and bumps. That’s a safety risk and expensive to fix. Geogrid fixes this by reinforcing the road base, boosting weight capacity, and preventing sinking.

When you’re on a road job, contractors lay geogrid right between the subgrade (natural soil under the road) and base course (gravel or crushed stone). This makes a stable platform that spreads vehicle weight evenly. Less pressure on the subgrade—no more sinking under big trucks. Reinforcing the base course stops soil from shifting or compacting over time. So roads stay smooth for years. A well-made geogrid retaining wall along roads does more than stop erosion—it spreads traffic weight evenly, cutting down on cracks from uneven pressure.

Geogrid’s especially helpful in soft soil areas. Trust me, I’ve dealt with this—traditional methods are a hassle. On rural jobs, you’d usually dig up and replace tons of soil. That’s expensive and takes forever. With geogrid, you skip costly steps like adding lime or cement. Those steps hurt the environment too, y’know? Instead, geogrid works with existing soil to make a stable foundation. Cuts time and costs. A big win for large road projects, where time and budget are tight.

The best part? Durability. By stopping the base course from shifting, geogrid reduces stress on asphalt or concrete. Fewer cracks, fewer potholes. Roads last longer, so less repairs and resurfacing. It also improves drainage—no water pooling in the base course to damage the road. That’s crucial in rainy areas—poor drainage ruins roads fast. Just how it is.

Slope Protection and Soil Conservation

Slope erosion and landslides are big headaches, especially in hilly or coastal spots. Unstable slopes risk nearby structures, infrastructure, and the environment. Geogrid offers a fix: it stabilizes slopes, stops erosion, and helps restore ecosystems.

In slope jobs, geogrid reinforces soil to make a stable surface that won’t shift. Contractors install it horizontally along the slope, then add gravel or soil between layers. This makes a reinforced structure that handles gravity and water runoff. The geogrid retaining wall here acts as a barrier to hold soil in place, but still lets water drain. That’s key to lowering landslide risk when water builds up. Vital in rainy or flood-prone areas—extra water weakens soil and triggers slides.

Geogrid also helps with soil conservation by stopping erosion. Its open holes let plants grow through, which further stabilizes slopes and cuts water impact. Plants absorb water, reduce erosion, and boost ecological health. Unlike old-school fixes—concrete walls or big rocks—geogrid lets plants grow naturally. No weird barriers. More eco-friendly. Super important in sensitive areas where preserving habitats matters.

Besides stability and green perks, geogrid’s cost-effective. Traditional slope methods need lots of materials and labor—expensive to install and maintain. Geogrid’s light and easy to put in, so it cuts labor time and costs. Less heavy machinery too, which helps the environment. Whether it’s highway slopes, residential hills, or restoration work, geogrid’s a practical, sustainable solution.

Future Trends and Industry Impact

Geogrid use will pick up real momentum in the next few years. This growth comes from demand for sustainable, affordable materials. As the industry focuses on green efficiency, geogrid’s set to become a standard for infrastructure. Better manufacturing will make it perform better and be more flexible, opening new uses.

One big trend now? Eco-friendly geogrid. Everyone’s leaning into sustainability, so manufacturers use more recycled materials. Cuts environmental impact—makes sense. New formulas also make it biodegradable, even greener. As the industry goes green, the geogrid retaining wall will get more essential. Manufacturers are focusing on recycled materials and easier installation for these walls.

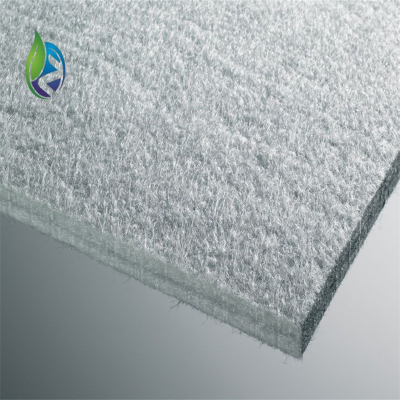

Another thing we’re seeing: mixing geogrid with other materials—geotextiles or geomembranes. This makes hybrid systems that work better: better drainage, filtration, erosion control. Perfect for complex projects like wastewater plants or coastal work. You have multiple challenges there, so combining geogrid with other gear lets engineers make custom solutions.

Geogrid’s also changing construction. Less heavy materials and digging mean lower costs and better efficiency. Plus, it cuts environmental harm, making projects more sustainable. As more engineers and contractors see its benefits, geogrid will spread. It’s changing how we plan and build infrastructure—slowly but surely.

Conclusion

High-strength geogrid’s a go-to material in modern engineering. It’s flexible, sustainable, affordable—great for reinforcing structures, stopping erosion, and stabilizing soil. From roads to slopes to municipal projects, it helps build durable, long-lasting structures. The geogrid retaining wall, in particular, is key—strong support that’s also green.

As construction evolves, demand for geogrid will grow. Driven by faster, safer, greener methods, better manufacturing will make it even better. Whether it’s a big infrastructure job or a small build, geogrid’s a cornerstone of modern engineering—helping build a more stable, sustainable future.

For engineers, contractors, and project managers wanting better stability and durability, geogrid’s a proven solution. Add it to designs, and you cut costs, boost efficiency, and minimize environmental impact—all while meeting top safety standards. In a world where infrastructure needs keep growing, geogrid isn’t just another material. It’s the foundation for successful, long-lasting projects.