How to Choose the Material of the Geogrid

How to Choose the Material of the Geogrid: A Complete Guide

Geogrids are essential materials used in civil engineering projects to reinforce soil, improve stability, and provide support in various construction applications. Whether you are working on road construction, embankment stabilization, or soil reinforcement, choosing the right material of the geogrid is crucial to ensure the success and durability of the project. In this guide, we will explore the factors to consider when selecting the ideal material of the geogrid for your project, ensuring that you make an informed and efficient choice.

What is a Geogrid?

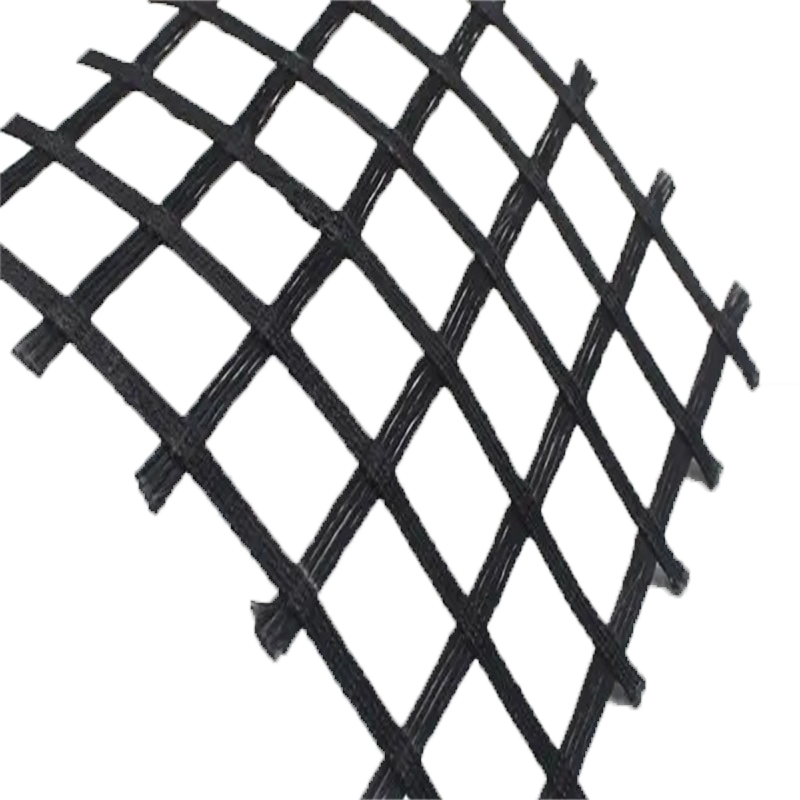

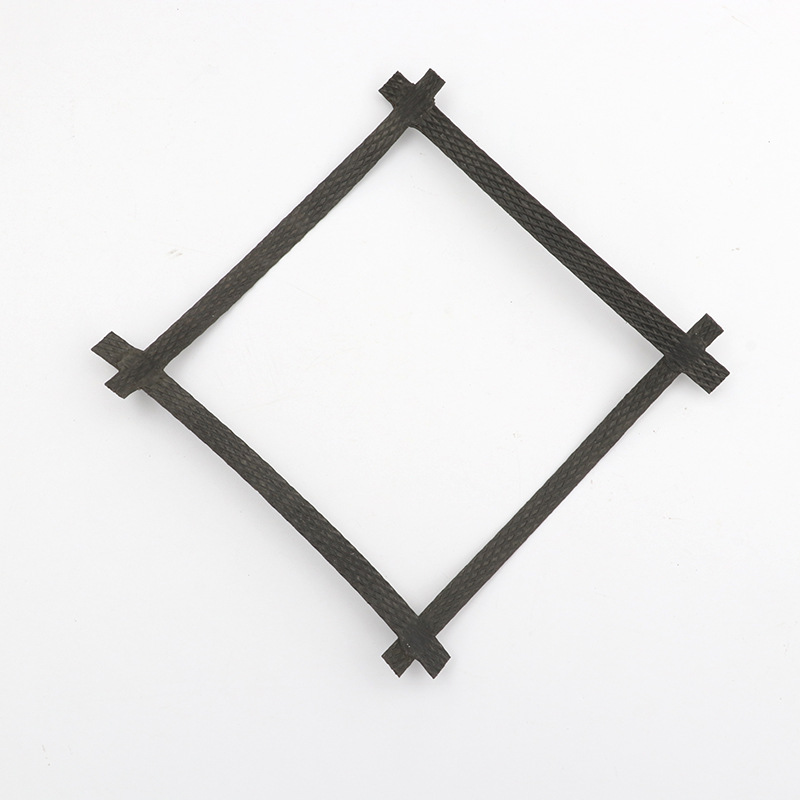

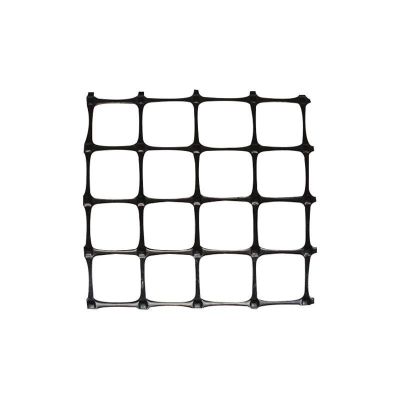

A geogrid is a geosynthetic material designed to reinforce and stabilize soil. It is typically made from polymers, including polyester, polyethylene, and polypropylene. These materials are manufactured in a grid-like structure that provides high tensile strength, enabling them to hold soil together, prevent erosion, and improve load-bearing capacity. Geogrids are used in various applications, such as road construction, retaining walls, and soil stabilization projects.

Why Is the Material of the Geogrid Important?

The material of the geogrid plays a critical role in determining the overall performance and effectiveness of the geogrid in any given application. The properties of the geogrid material, such as tensile strength, durability, resistance to environmental factors, and ease of installation, influence its ability to perform under various stress conditions.

Choosing the wrong material can result in insufficient soil stabilization, erosion, or failure of the structure over time. Therefore, it is essential to consider several key factors when selecting the material of the geogrid for your project.

Key Factors to Consider When Choosing the Material of the Geogrid

1. Tensile Strength

Tensile strength is one of the most important properties to consider when selecting the material of the geogrid. Geogrids are primarily designed to withstand tension, so it is essential to choose a material that offers the required tensile strength for the application. For projects involving heavy loads, such as roadways or embankments, a material with high tensile strength is necessary to prevent deformation and failure.

Polyester and high-density polyethylene (HDPE) geogrids are known for their superior tensile strength, making them ideal for heavy-duty applications.

2. Durability and Longevity

The material of the geogrid must be durable enough to withstand the environmental conditions it will be exposed to throughout the life of the project. Geogrids are often buried underground or exposed to harsh weather conditions, so the material should be resistant to degradation caused by factors like UV radiation, moisture, and temperature fluctuations.

Polypropylene and polyethylene geogrids are highly durable and resistant to chemical and biological degradation, making them ideal for long-term use in various environmental conditions.

3. Environmental Resistance

Different geogrid materials offer varying degrees of resistance to environmental factors. For example, UV resistance is essential for geogrids exposed to sunlight, as prolonged exposure to UV radiation can cause degradation and reduce the material's effectiveness.

Materials like polypropylene and polyethylene offer excellent UV resistance and are commonly used for outdoor and exposed applications. On the other hand, polyester geogrids are suitable for more controlled environments where UV exposure is less of a concern.

4. Installation Ease and Cost

The ease of installation is another critical factor to consider when choosing the material of the geogrid. Some geogrid materials, like polyester, are more flexible and easier to install, making them ideal for projects where quick and efficient installation is necessary. However, more rigid materials like HDPE geogrids may require additional equipment for installation but provide higher long-term performance.

Cost is also a significant consideration. While materials like polyester may have higher upfront costs, their long-lasting durability and performance can provide cost savings over time, particularly in demanding applications.

5. Load-Bearing Capacity

The load-bearing capacity of the geogrid material is essential for projects that require soil reinforcement to support heavy loads, such as roads, railways, or embankments. Polyester geogrids, for example, are known for their high load-bearing capacity, making them ideal for use in high-stress environments.

Polyethylene and polypropylene geogrids, while more affordable, are better suited for less demanding applications.

6. Chemical Resistance

Certain applications, such as projects in industrial zones or areas with contamination risks, may require geogrids with strong chemical resistance. The material of the geogrid should be resistant to chemicals, oils, and solvents that may be present in the environment.

Polypropylene and polyethylene geogrids offer excellent chemical resistance, making them suitable for use in environments where chemical exposure is a concern.

7. Application-Specific Requirements

Finally, it’s essential to consider the specific needs of your project when choosing the material of the geogrid. For example, in road construction, the geogrid must be able to withstand traffic loads and prevent soil erosion, while in landfill projects, the geogrid may need to offer high resistance to punctures and tears.

The selection of material may vary depending on whether the project is for road construction, slope stabilization, retaining walls, or foundation reinforcement. Each application has unique requirements, so the material should be chosen to meet those needs.

Common Geogrid Materials and Their Applications

1. Polyester (PET) Geogrids

Polyester geogrids are known for their high tensile strength, durability, and ability to withstand high loads. They are often used in heavy-duty applications, such as road construction, railroads, and embankments. They are also resistant to chemical degradation, making them suitable for use in a variety of environments.

2. Polyethylene (HDPE) Geogrids

HDPE geogrids are ideal for applications requiring high load-bearing capacity and resistance to environmental degradation. They are commonly used in soil reinforcement, erosion control, and foundation stabilization. They also offer excellent UV resistance, making them suitable for outdoor applications.

3. Polypropylene (PP) Geogrids

Polypropylene geogrids are flexible, cost-effective, and ideal for projects with lower load requirements. They are used in a wide range of applications, including slope stabilization, foundation reinforcement, and retaining walls. They offer good chemical resistance and UV stability.

4. Glass Fiber Geogrids

Glass fiber geogrids are often used in applications requiring high strength and resistance to cracking. They are commonly used in pavements, road reinforcement, and soil stabilization projects. They offer exceptional durability and resistance to chemical and biological degradation.

Conclusion

Choosing the right material of the geogrid is essential for ensuring the success and longevity of your construction project. Factors such as tensile strength, durability, environmental resistance, and cost should all be considered when making your selection. Polyester, polyethylene, and polypropylene geogrids each offer distinct advantages depending on the specific needs of your project. By understanding these factors and selecting the right geogrid material, you can ensure that your project remains stable, secure, and durable for years to come.