Geomembrane for Landfill Site

Landfill site geomembranes, such as the High Density Polyethylene (HDPE) geomembrane, play a vital role in modern waste management practices by providing a robust barrier system to contain and isolate waste materials from the surrounding environment. These geomembranes are engineered with high impermeability, durability, and chemical resistance properties to effectively prevent the leakage of contaminants, such as leachate, into the soil and groundwater.

Support bulk ordering with favorable prices.

Support ODM/OEM.

The factory has stock and fast delivery.

Delivery Time: 10-20 working days

Minimum Order Quantity: 300 square meters

Payment Term: 30% T/T Deposit, 70% T/T Before Shipping

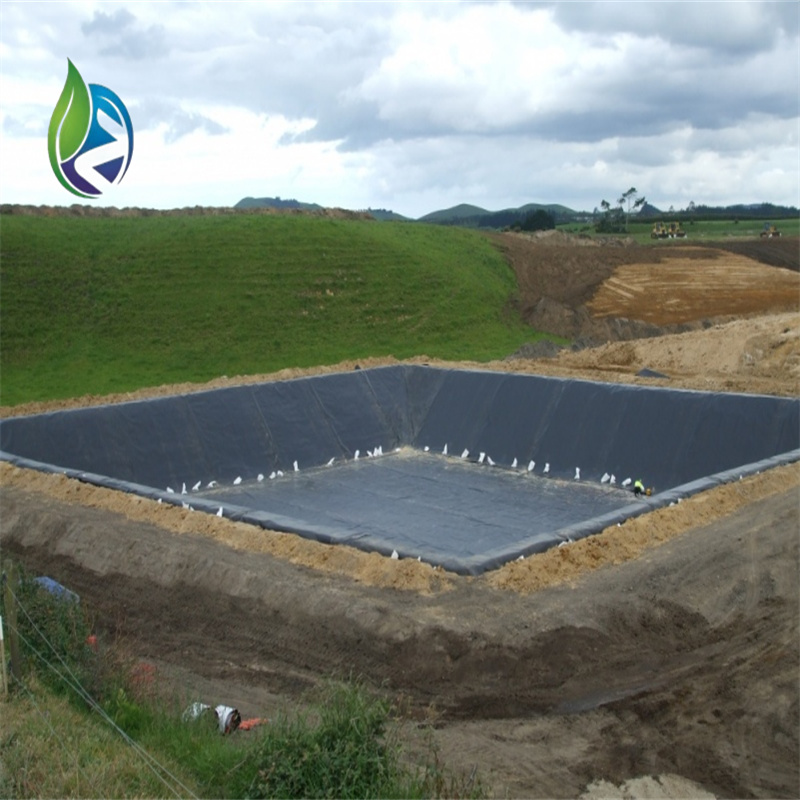

In today’s world, proper waste management is more than a necessity—it’s a responsibility. A geomembrane for landfill site is one of the most crucial components in ensuring that landfill operations are safe, sustainable, and fully compliant with environmental regulations. Whether you are planning a municipal landfill, industrial waste site, or hazardous material storage area, choosing the right geomembrane is essential to long-term success.

? What Is a Geomembrane for Landfill Site?

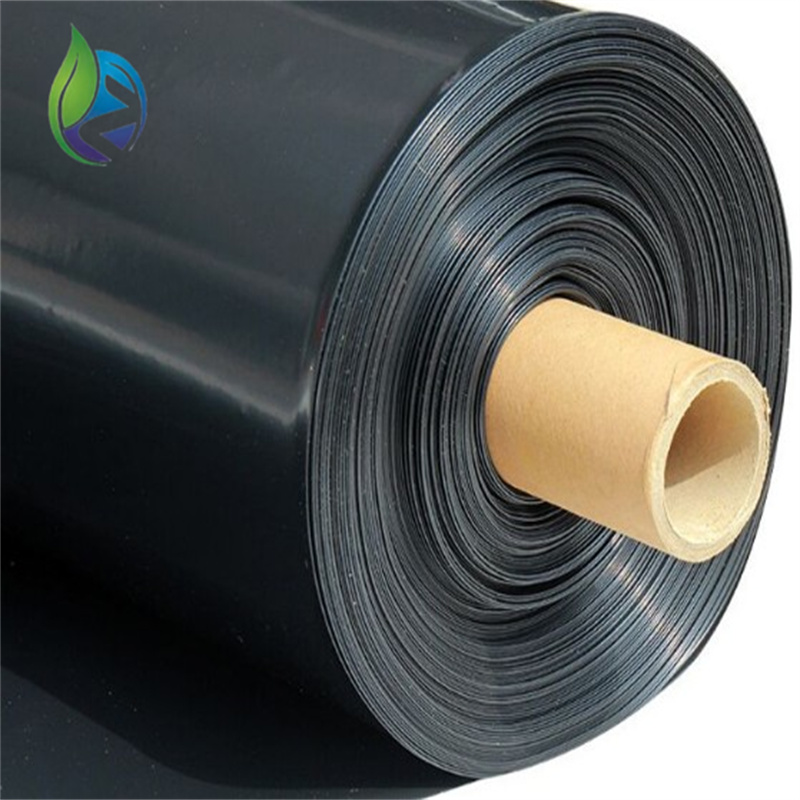

A geomembrane for landfill site is a low-permeability synthetic membrane liner designed to act as a barrier to liquids and gases. It is typically installed at the base and sides of a landfill cell to prevent leachate from contaminating surrounding soil and groundwater. These membranes are most commonly made from HDPE (High-Density Polyethylene) due to its excellent chemical resistance, long service life, and cost-efficiency.

Think of it as the invisible shield beneath a landfill—holding back pollutants, protecting our earth.

? Key Features & Benefits

Here’s why engineers, contractors, and environmental specialists choose geomembrane for landfill site as the gold standard in liner systems:

✅ Exceptional Chemical Resistance: Withstands acids, alkalis, and heavy metals found in landfill leachate.

✅ UV & Ozone Resistant: Suitable for exposed installations in harsh climates.

✅ High Tensile Strength: Resists stress from settlement and waste pressure.

✅ Thermally Weldable Seams: Ensures complete impermeability and ease of installation.

✅ Long Lifespan (50+ years): Proven performance for decades of landfill operation.

✅ Compliance with Global Standards: Meets ASTM, GRI-GM13, and ISO certifications.

“You build a landfill once, but the consequences last for generations. A quality geomembrane makes the difference.”

?️ Applications Beyond the Base

While geomembrane for landfill site is primarily used as a base liner, it plays multiple roles across different landfill components:

Bottom liner system: Forms the primary containment layer.

Capping/closure system: Prevents water ingress and reduces gas emissions after landfill closure.

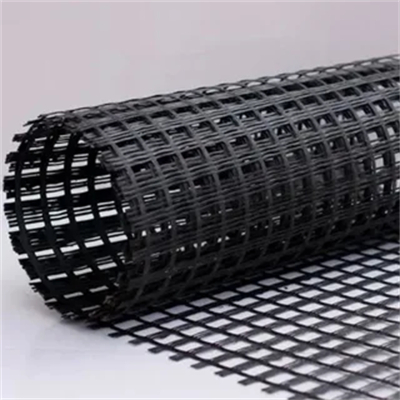

Leachate collection layer: Installed in combination with drainage geonets.

Gas barrier system: Helps contain methane and other landfill gases.

? Technical Specifications (Typical HDPE Geomembrane)

| Property | Value |

|---|---|

| Thickness | 0.75mm – 2.5mm |

| Density | ≥0.94 g/cm³ |

| Tensile Strength | ≥28 MPa |

| Elongation at Break | ≥700% |

| Puncture Resistance | High (≥600 N) |

| Temperature Range | -60°C to +85°C |

| Lifespan | 50+ years in buried applications |

? Real User Feedback

⭐⭐⭐⭐⭐

"We’ve used this HDPE geomembrane on two large-scale landfill projects and have been impressed with the durability and weld quality. Zero leakage so far—absolutely reliable."

— Carlos M., Project Engineer, Argentina

⭐⭐⭐⭐☆

“Installation was fast and the material was flexible even in cold weather. It’s great knowing the groundwater around our site is fully protected.”

— Sarah L., Environmental Consultant, Canada

⭐⭐⭐⭐⭐

“We opted for a textured geomembrane for a sloped area, and the added friction helped avoid slippage during backfilling. Great product and responsive supplier!”

— Rajeev K., Landfill Manager, India

? Why HDPE Is the Industry Standard

Among all geomembrane materials, HDPE geomembrane for landfill site is the most widely accepted due to its:

Low permeability to liquids and gases

High resistance to UV, chemical exposure, and biological degradation

Cost-effectiveness for large-scale projects

Proven track record in landfill engineering worldwide

While LLDPE or PVC alternatives exist, HDPE provides the best balance of durability, lifespan, and cost—especially in high-volume applications like municipal solid waste (MSW) landfills.

? Sustainability & Environmental Impact

Using a geomembrane for landfill site not only helps comply with environmental regulations—it actively prevents ecological damage. A well-installed liner can:

Protect groundwater from toxic leachate

Reduce greenhouse gas emissions through effective capping

Prevent soil contamination in surrounding areas

Ensure regulatory approval and public trust in your waste management project

Geomembrane liners are a frontline defense in the fight for a cleaner planet.

? Ordering & Customization

Whether you’re sourcing for a government landfill, private waste site, or environmental remediation project, we provide:

✅ Thickness Options: 0.75mm to 2.5mm

✅ Smooth & Textured Surfaces

✅ Black, Green, or Custom Colors

✅ Roll Widths Up to 8 meters

✅ On-Site Installation Support Available

II. Specialized Functions

1. Thermal Regulation

Black geomembranes: Absorb solar radiation to raise soil/water temperature (increase winter water temperature by 2-5°C), used in aquaculture overwintering.

White/reflective geomembranes: Reflect heat to mitigate summer high-temperature impacts on roadbeds.

2. Gas Venting

Textured surfaces: Structured geomembranes (e.g., rough HDPE) facilitate biogas emission for landfill methane recovery systems.

3. Interface Stability

Frictional properties: Friction angles of 25°-35° between textured geomembranes and soil enhance slope anti-sliding capacity (e.g., steep slope cover systems).