Landscape Fabric Geotexitle

Manufacturing Process

Landscape Fabric Geotextile is produced through continuous industrial textile processing.

Polypropylene chip drying and metered feeding.

Melt spinning into continuous filaments or staple fibers.

Web formation by carding and cross-lapping.

Needle-punch consolidation using high-speed looms.

Thermal bonding through calibrated heated rollers.

Online thickness and mass monitoring with laser sensors.

Slitting, rolling, and batch-coded packaging.

Product Definition

Landscape Fabric Geotextile is a permeable synthetic textile material engineered to separate, filter, reinforce, and stabilize soil layers in landscape and civil works. It controls weed growth, prevents soil migration, enhances drainage performance, and extends the structural service life of landscaped and paved systems.

Technical Parameters and Specifications

Landscape Fabric Geotextile is designed with controlled permeability, mechanical strength, and durability for long-term outdoor exposure.

| Parameter | Typical Range | Test Standard |

|---|---|---|

| Mass per Unit Area | 80–300 g/m² | ASTM D5261 |

| Tensile Strength (MD/CD) | 8–20 kN/m | ASTM D4595 |

| Elongation at Break | 40–80% | ASTM D4595 |

| CBR Puncture Resistance | 1.2–3.5 kN | ASTM D6241 |

| Water Flow Rate | 80–150 L/m²/s | ASTM D4491 |

| UV Resistance (500 h retention) | ≥ 70% | ASTM D4355 |

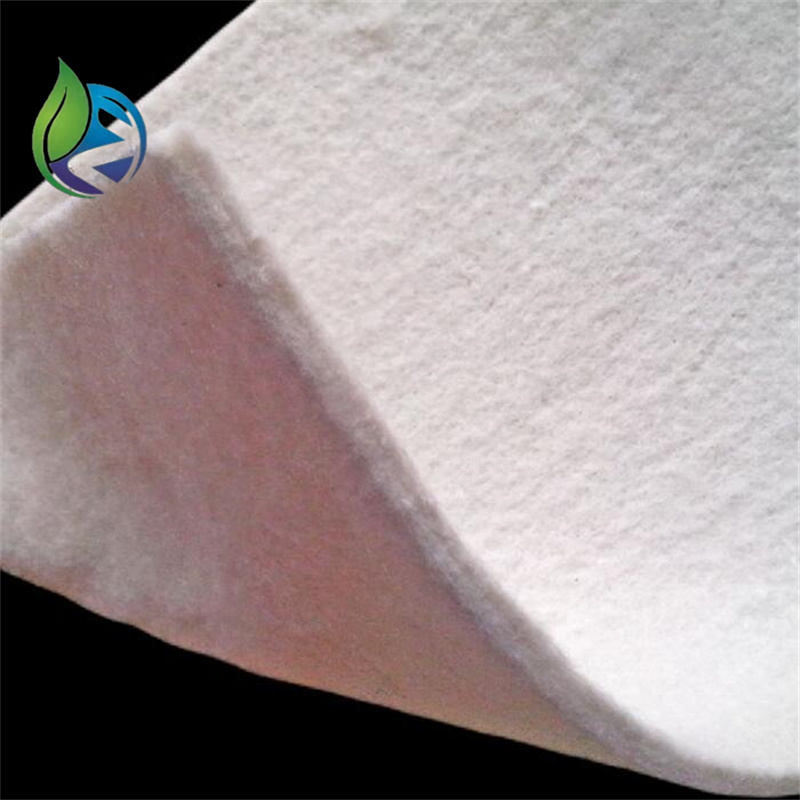

Structure and Material Composition

Landscape Fabric Geotextile uses a layered fibrous structure optimized for filtration and separation.

Top Surface Layer: UV-stabilized polypropylene fibers

Core Matrix: Needle-punched nonwoven fiber network

Bottom Support Layer: Thermally bonded stabilization surface

Edge Finish: Heat-sealed or ultrasonically cut edges

Additives: Carbon black and antioxidant stabilizers

Manufacturing Process

Landscape Fabric Geotextile is produced through continuous industrial textile processing.

Polypropylene chip drying and metered feeding.

Melt spinning into continuous filaments or staple fibers.

Web formation by carding and cross-lapping.

Needle-punch consolidation using high-speed looms.

Thermal bonding through calibrated heated rollers.

Online thickness and mass monitoring with laser sensors.

Slitting, rolling, and batch-coded packaging.

Industry Comparison

| Material Type | Separation Efficiency | Drainage Capacity | Durability | Installation Complexity |

|---|---|---|---|---|

| Landscape Fabric Geotextile | High | High | High | Low |

| Woven Plastic Sheets | Medium | Low | Medium | Low |

| Organic Mulch Layers | Low | Medium | Low | Medium |

| Gravel-Only Systems | Low | High | High | High |

Application Scenarios

Landscape Fabric Geotextile is engineered for distributors, EPC contractors, and engineering developers across multiple landscape and infrastructure projects.

Roadside landscaping and slope stabilization

Garden and urban park weed control systems

Green roof drainage separation layers

Pavement subbase separation in walkways and plazas

Sports field and playground construction

Core Problems and Engineering Solutions

Problem: Soil migration into drainage layers

Solution: Controlled pore structure for long-term filtration.Problem: Weed penetration through landscape systems

Solution: Dense fiber matrix blocks light and root growth.Problem: Poor subbase stability

Solution: High tensile reinforcement distributes loads.Problem: Premature material degradation

Solution: UV-stabilized polymers extend exposure service life.

Risk Warnings and Mitigation Recommendations

Avoid excessive tension during installation to prevent fiber distortion.

Prevent direct long-term sunlight exposure before cover placement.

Remove sharp stones and roots from subgrade before positioning.

Use recommended overlap widths at joints and edges.

Procurement and Selection Guide

Define project load classes and soil condition categories.

Calculate required tensile strength and puncture resistance.

Verify hydraulic flow requirements for drainage performance.

Confirm UV resistance requirements based on exposure time.

Specify roll width and cut tolerances for site layout.

Request third-party laboratory test reports.

Verify manufacturing quality management certifications.

Engineering Case Study

In an urban park redevelopment project of 12,000 m², Landscape Fabric Geotextile with 150 g/m² mass was installed under gravel walkways and planting zones. Post-installation monitoring over 24 months confirmed stable drainage performance and complete suppression of soil pumping into the surface layers.

FAQ

Q1: What is the typical service life?

A: 10–25 years depending on exposure and load conditions.Q2: Can it be used under vehicle loads?

A: Yes, with appropriate strength class selection.Q3: Is it environmentally safe?

A: Yes, inert polypropylene does not leach harmful substances.Q4: What overlap width is recommended?

A: Typically 200–300 mm.Q5: Can it be cut on site?

A: Yes, with standard cutting tools.Q6: Does it require special anchoring?

A: Only mechanical or soil pin fixing.Q7: Is it compatible with drip irrigation?

A: Yes, water permeability supports irrigation systems.Q8: Can it be used on steep slopes?

A: Yes, with anchoring and overlap control.Q9: What standards apply to quality control?

A: ASTM, EN, and ISO geotextile standards.Q10: How is field performance verified?

A: Visual inspection and permeability spot testing.

CTA

Procurement departments and engineering consultants may request quotations, technical data sheets, and project-specific material samples for Landscape Fabric Geotextile through formal technical inquiry to support accurate specification and tender preparation.

E-E-A-T Author Credentials

This technical content is prepared by a senior geotechnical materials engineer with over 15 years of professional experience in geotextile system design, field supervision, and international infrastructure project consulting,参与多项行业标准评审与工程质量验收技术工作。